Contemporary businesses are powered by data. In the present-day environment, it is vitally crucial for organizations to collect and scrutinize data to optimally serve their clientele and streamline their processes. The data sector also plays a pivotal role in propelling the worldwide economy ahead as companies globally channel substantial investments into fresh tools, technologies, and infrastructures that can competently handle their far-reaching digital archives.

This scenario undoubtedly resembles that of a certain multinational corporation, which has recently channeled over $50 million into the erection of two buildings in the vicinity of its extensive headquarters. One of these new constructs, a 38,000-square-foot data center, notably enhances the enterprise’s secure data storage capacities in the North American market. The introduction of this state-of-the-art data center enables the company to efficiently handle and dissect massive volumes of information received from its consumers, vendors, and beyond.

In this scenario, a data center generator is crucial and these are the details of a project to design and build one.

We invite you to read the details below.

A Reliable and Redundant Solution

KOHLER® POWER EQUIPMENT

Three -2000-kW Diesel Generators

Switchgear Automatic Transfer Switches

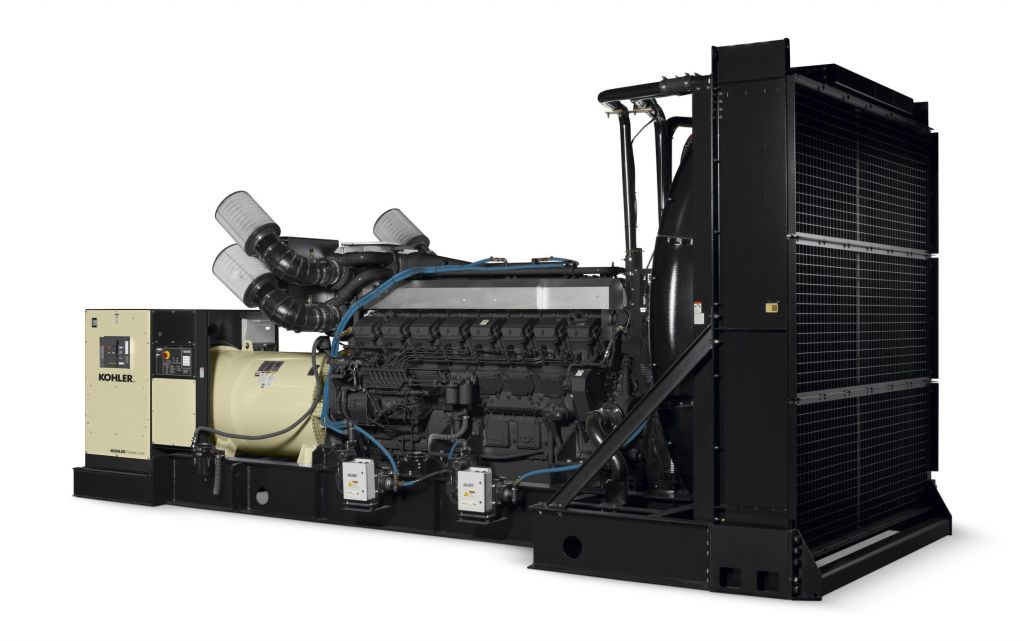

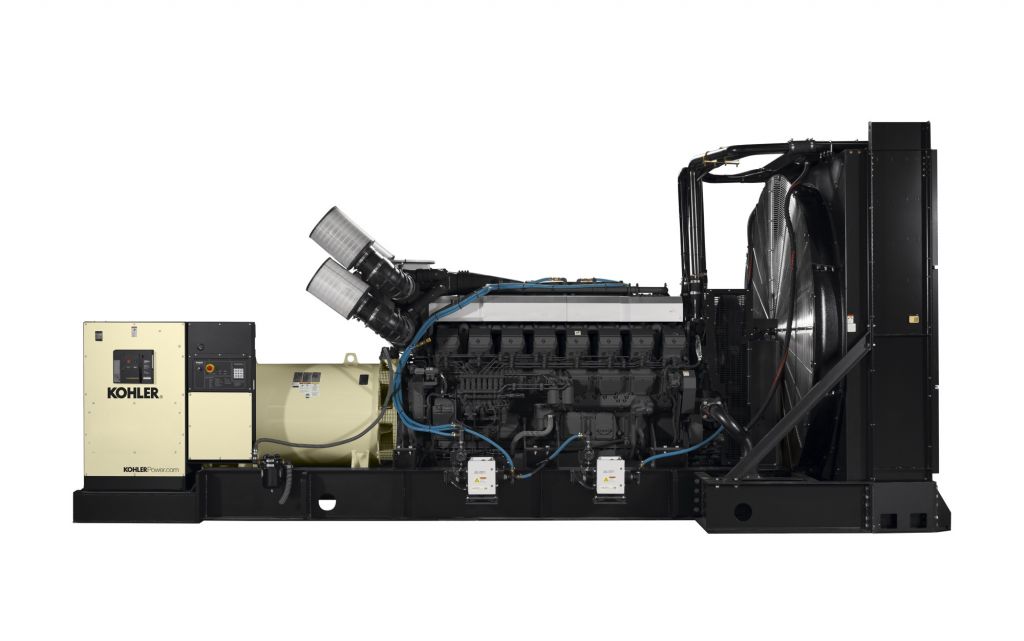

Three KOHLER® generators, specifically the 2000REOZMD model, were pinpointed as the perfect solution for the vast, new data center. These generators – set up in parallel – supply ample power to backup the center and its plethora of intricate systems. The arrangement also caters to redundancy and risk mitigation, ensuring that the sensitive data retains its safety, security, and accessibility.

Every one of the three 2000-kW KOHLER generators boasts a robust diesel engine, in addition to a brushless alternator with a permanent magnetic pilot exciter for superb load response. These 60-Hz generators have achieved a UL 2200 listing, comply with NFPA 110, Level 1, and were put through a prototype examination, factory assembly and production testing before installation.

To flawlessly join the void between utility power loss and standby power, KOHLER 880A automatic transfer switches (ATS) were incorporated. The ATS employed for the data center comprise of KOHLER-engineered and constructed MPAC® controllers, which provide complete system management and an array of user-friendly features. These include a user-friendly LCD display, LED-indicated source status and switch position, alongside programmable pickup and dropout voltage.

Tailor-made KOHLER PD-Series switchgear was also designed specifically for the project, underlining the advantages of Kohler’s comprehensive system integration.

“The switchgear wasn’t part of the initial bid, but after consulting with our engineers, learning more about our expertise in this area and seeing some of the massive datacenters Kohler has been working with on a global scale, they wanted to move forward with our team’s solution”. “By installing a complete KOHLER power system, this company can now rest assured knowing every component–from generator and transfer switch to paralleling switchgear and controller–was designed, built and tested to work together and provide complete dependability.”

In an effort to ensure the new KOHLER power system remains safeguarded and secure, and simultaneously protecting the generators from inclement weather, these units were mounted within an enclosure made of sound-attenuated aluminum. Platforms and stairs were also incorporated for the convenience of service personnel.

The KOHLER® 2000REOZMD

The KOHLER® 2000REOZMD is the embodiment of modern innovation in power solutions, serving as the quintessential energy generator for industries worldwide. As a formidable model in KOHLER’s vast catalog of power solutions, it carries unique features that make it stand out from its competition.

The KOHLER 2000REOZMD generator harnesses the power of a robust diesel engine, inherently designed to provide superior performance, unparalleled reliability, and impressive durability. The engine’s efficiency is further amplified by KOHLER’s industry-leading fuel system, designed to ensure maximum energy output while minimizing fuel consumption.

Offsetting this powerhouse is a brushless alternator with a permanent magnetic pilot exciter. This advanced technology offers superb load response by providing immediate voltage regulation in the event of load changes. This means that when the power demand spikes or dips, the generator swiftly adjusts to the variation, thus ensuring steady power supply.

With a massive 2000-kilowatt power output, this generator model can adequately service sizable facilities. Despite its immense output, the generator remains energy efficient, a testament to KOHLER’s commitment to sustainable and ecological power solutions.

Beyond its engine prowess, the KOHLER 2000REOZMD has received UL 2200 listing approval and meets NFPA 110, Level 1. The significance of such certifications cannot be overstressed. It implies that the generator has been subjected to, and passed rigorous testing and evaluation processes, thereby exceeding standard expectations for safety, performance, and reliability.

One of the completely unique features of the KOHLER 2000REOZMD is its prototype testing, a crucial step in the QA process. Factory-built and production-tested prior to installation, each generator’s function, performance, and reliability are certified to meet KOHLER’s exceptionally high standards.

Portability is another crucial aspect of this generator. Despite its high-octane performance, the KOHLER 2000REOZMD is designed to be compact and relatively easy to transport, allowing businesses to relocate the generator as their needs dictate.

Furthermore, the generator is housed within a sound-attenuated aluminum enclosure that keeps it safe from harsh environmental elements, while simultaneously containing the noise produced during operation. This is extremely beneficial in reducing noise pollution in the environment where it operates.

For accessibility, the model comes with platforms and stairs, designed to facilitate seamless and safe access for service personnel. This makes regular maintenance checks and potential repairs a lot easier and safer, thus ensuring a longer lifespan for the generator.

The KOHLER 2000REOZMD generator model also offers integration with KOHLER’s automatic transfer switches (ATS) and PD-Series switchgear. This seamless integration warrants a comprehensive, reliable, and redundant power backup system that can instantly take over in the event of a power outage, ensuring that your operations aren’t missed a beat.

In summary, the 2000REOZMD generator serves as an epitome of KOHLER’s dedication to quality, technological innovation, and customer satisfaction. It provides reliable power solutions interlaced with advanced features designed to handle a wide range of power requirements while simultaneously delivering efficiency, accessibility, and dependability.

KOHLER® 2000REOZMD Technical Documents

In the following links you will find all the technical documents related to the KOHLER® 2000REOZMD used in this case study: