Corrosion poses a severe threat to the longevity and functionality of power generating equipment. This menace is raw and dangerously real for marine power generators or non-marine power generators exposed to saltpeter.

In this article, we will delve into the intricacies of corrosion in power generating equipment, examining causative factors, real-life scenarios where equipment is susceptible to corrosion, and methods to prevent it. The objective is to provide a comprehensive guide for the optimal maintenance of your power generator equipment when the equipment is operating in situations where it is susceptible to corrosion.

Corrosion is an intricate chemical process that occurs when materials, particularly metals, interact with their environment. In the realm of power generation, comprehending corrosion in power generators is imperative for ensuring the longevity and reliability of these critical assets.

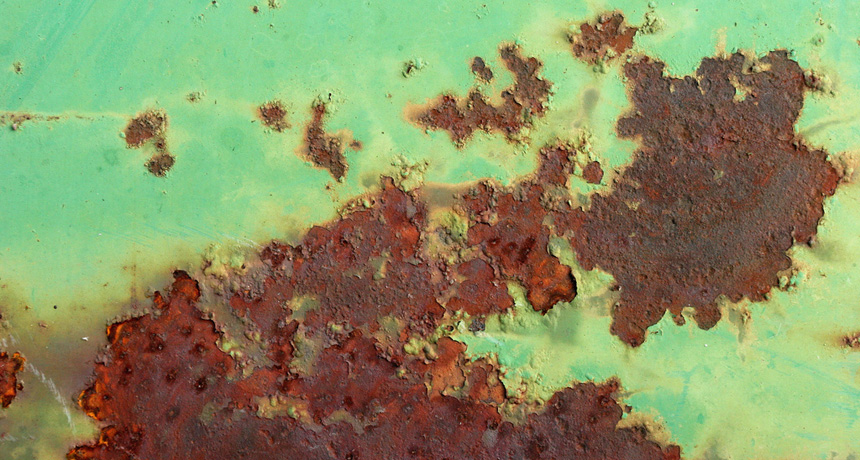

At its core, corrosion involves the deterioration of materials due to electrochemical reactions, often accelerated by factors such as moisture, salts, and contaminants. In the context of power generators, these reactions manifest as a gradual degradation of structural integrity, potentially compromising performance and safety.

The corrosion in power generators is a multifaceted challenge. Various components, including turbine blades, heat exchangers, and condensers, are susceptible to corrosive forces. The hostile environment within power generation systems, characterized by high temperatures, pressure differentials, and chemical variations, exacerbates the corrosion process.

Understanding the intricacies of corrosion in power generators necessitates delving into the electrochemical mechanisms. Anode and cathode reactions, along with electrolyte presence, contribute to the corrosion milieu. The formation of corrosive by-products, such as rust and oxides, further accelerates material degradation.

Causes of Corrosion

The complex process of corrosion involves several contributory factors and distinct stages.

At its core, corrosion is an electrochemical reaction where metal reacts with an electrolyte to form a more stable compound, such as an oxide, hydroxide, or salt. It’s essentially the natural process by which metals revert to their unrefined ore state. The propensity of a specific metal to corrode depends essentially on its inherent chemical properties.

One prominent factor causing corrosion in power generators is their exposure to environmental extremes. For instance, salt-laden air in coastal areas is notorious for accelerating the corrosion process. Contaminants in water, especially when the water is acting as an electrolyte, can further exacerbate the corrosion process.

Other factors include the temperature, which can boost the rate of certain corrosive reactions and the contact with different metals. In power generators, this occurrence is commonplace where different metal types are used in construction, creating a galvanic cell promoting corrosion.

Fluid flow rates can have a significant impact since slow-moving or stagnant water can lead to localized concentration changes in the corrosive agents, often leading to pitting, a form of highly localized corrosion.

Furthermore, the design and operation of the power generators can inadvertently encourage corrosion. An instance is internal surfaces not being properly cleaned to remove debris and contaminants during construction, creating sites liable to corrosion.

Finally, factors like microbial activity, specifically bacteria that produce sulfides, can induce corrosion.

Stopping corrosion in power generators necessitates understanding these underlying causes and taking appropriate action, such as proper material selection, design modifications, protective coatings, and corrosion inhibitors. Implementing corrosion management strategies is invaluable to optimize the longevity and efficiency of power generators and preclude unnecessary repair and replacement costs.

Impacts of Corrosion On Power Generators

The detrimental impacts of corrosion on power generators are far-reaching and can significantly influence their efficiency, performance, and service life. Corrosion in power generators essentially manifests as a progressive degradation of the material making up the generator components. The series of material losses subsequently result in deterioration of the machinery, affecting its overall life expectancy and operational reliability.

One primary impact is the reduction in the thickness of components. This thinning can lead to leaks, breaks, and overall structural failures, which can be catastrophic, especially in critical load carrying components. For example, corrosion in the generator’s coolant system may lead to coolant leakage, causing overheating and potential system failure.

Another significant impact is the onset of large systemic losses incurred due to unplanned outages, breakdowns, and equipment shutdowns. Operations may be halted for corrective maintenance, or worse, replaced altogether. The financial implications of these stoppages are often substantial.

Electrical conductivity is another area where corrosion in power generators can wreak havoc. Corroded connections can lead to elevated contact resistance, resulting in inadequate current flow, overheating, arcing, or fire hazards.

Perhaps one of the most insidious effects of corrosion in power generators is the so-called ‘pitting corrosion,’ a localized form of corrosion. These pit formations can lead to stress concentration areas that are more prone to fracturing under mechanical stresses.

Furthermore, corrosion can directly impact the performance of the power generator. Deposits formed due to corrosion, say in fuel or cooling systems, can hinder the efficient transfer of heat within systems. This gunk leads to inefficient operation, higher energy costs, and decreased functional lifespans.

Corrosion in power generators is not a minor worry but a critical issue that can lead to severe systemic and operational failures, threatening the reliability and efficiency of power generators. Understanding the substantial impacts of corrosion can vindicate the need for integrated corrosion management strategies to prolong the functionality and serviceability of power generators.

Types of Corrosion On Power Generators

Corrosion On Marine Power Generators

Corrosion in power generators presents an unfavorable and costly challenge to many industries, but it is the marine sector that particularly faces the brunt of this destructive phenomenon. The problem is especially prominent in marine power generators due to their constant exposure to harsh, corrosive conditions.

Primarily, marine power generators are regularly exposed to saltwater – a potent electrolyte catalyzing corrosion. When the metallic components of the power generators come into contact with saltwater, it sets off an electrochemical reaction – ultimately leading to the substantial deterioration of these components.

An additional exacerbating factor for corrosion in marine power generators within marine environments is the high humidity levels. This excessive moisture can foster an environment nourishing the corrosion process, leading to what is often referred to as ‘rust,’ the visible sign of corrosion. Therefore, in such conditions, strict and regular maintenance becomes more than a necessity.

As a consequence of the corrosion, these marine power generators face several potential detrimental effects. The effectiveness of the power output can be notably compromised, and in severe cases, lead to the complete malfunction of the generator. Moreover, the depreciation in reliability and consequently, in efficiency, means an increased financial overhead due to more frequent maintenance checks and component replacements.

Of heightened concern is the abrupt failure of a generator while at sea, which can pose serious safety risks. Abrupt power loss in extreme marine environments can lead to disastrous situations, endangering lives and equipment.

To circumvent the adverse impacts of corrosion in marine power generators, especially in marine applications, it is crucial to implement comprehensive anti-corrosion strategies. These might include regular inspection and maintenance, installation of sacrificial anodes, and protective coatings that prevent the metal parts from the marine environment.

Corrosion in marine power generators can undermine the safety and smooth operation of marine activities. Thus, understanding the factors contributing to corrosion and implementing a pro-active, routine maintenance plan can substantially defend against corrosion and prolong the lifespan of marine power generators.

Corrosion On Non-Marine Power Generators

While corrosion in power generators is typically associated with marine environments, non-marine power generators are also not immune to it. It’s crucial to note that while corrosion might manifest somewhat differently, the impacts remain detrimental for these types of generators.

Corrosion in power generators can happen in various non-marine settings, predominantly determined by the type of atmosphere the generators are subjected to. For instance, power generators installed in industrial environments where they are exposed to corrosive gasses can significantly hasten corrosion. Similarly, generators placed in areas with high air pollution or near the coast where there is substantial saltpeter in the air are similarly prone to accelerated corrosion.

The ‘when’ of corrosion in power generators in a non-marine setting depends on several factors. The rate of corrosion can be influenced by the quality of maintenance, materials used for construction, proximity to corrosive substances, and environmental parameters such as temperature and humidity.

While corrosion in power generators happens universally, being aware of specific circumstances in non-marine environments can help implement effective preventive and protective measures to maintain the generators’ reliability and longevity.

Comprehensive Measures to Prevent Corrosion

Integrating comprehensive measures against corrosion in power generators can be a rewarding and far-sighted approach to maintaining their optimal performance and longevity. Both marine and non-marine power generators can benefit significantly from proactive prevention techniques, effectively saving operational and replacement costs over time.

Protective Coatings: A primary line of defense against corrosion in power generators is using high-quality, industrial-grade protective coatings. These coatings, spanning from epoxy to zinc-rich coatings, create a barrier, resisting the corrosive electrolyte and blocking the electrochemical corrosion process.

Cathodic Protection: Cathodic protection is a widely utilized method which halts the corrosion process by transforming all the metal surfaces into cathodes of an electrochemical cell. Two popular techniques include the use of sacrificial anodes or impressed current systems.

Humidity control: Dehumidification or moisture control is notably effective in preventing corrosion, especially in non-marine power generators. By maintaining a relative humidity less than 60%, the corrosion process can be inhibited drastically.

Routine Maintenance and Inspection: Regular maintenance and inspections cannot be overstated. Cleaning accessible parts regularly to remove salt deposits or pollutants, along with routine check-ups for early signs of corrosion, are paramount in proactively managing corrosion in power generators. (See below for more details)

Sealing and Isolation: Protect sensitive areas by using seals and isolators, and encase power generators in a protective enclosure wherever possible to protect them from exposure to corrosive substances.

Mitigating corrosion in power generators entails a combination of adequate material selection, diligent maintenance, effective use of protective coatings, and application of advanced strategies like cathodic protection. Understanding the environment in which the generator operates, be it marine or non-marine, is also vital in developing a tailor-made corrosion prevention strategy.

Routine Maintenance

Diligent and detailed routine maintenance encompasses one of the paramount strategies against corrosion in power generators. Whether in marine or non-marine environments, the consistent upkeep of these power generation units can dramatically minimize the corrosive impact, extending the longevity and reliability of the equipment.

Visual Inspection: A simple yet significant part of routine maintenance is conducting regular visual inspections. Look for discoloration, pitting or flaking on the generator surface. These signs often indicate the onset of corrosion.

Cleaning: Regular cleaning, particularly in marine environments, is vital. Power generators ideally should be cleaned to remove salt deposits, dust, or any pollutants. This task becomes critical for non-marine power generators exposed to high levels of pollution or near coastal areas with high atmospheric saltpeter.

Corrosion Inhibitors: The application of corrosion inhibitors, substances that slow down or prevent corrosion in power generators, should be a part of the regular upkeep. These inhibitors form a protective film over the metal surface, stopping further progression of corrosion.

Regular Coating Inspection: Inspect the integrity of the protective coatings routinely. Any chips or scratches in the coating expose the underlying metal to corrosion. Prompt repair of those compromised areas ensures the coating’s efficacy.

Parts Replacement: Routine maintenance should also include checks for parts that have already suffered from corrosion. The replacement of corroded parts helps in maintaining the overall structural integrity and functionality of the power generator.

Environment Control: For indoor, non-marine generators, maintaining a controlled environment can be beneficial. Ensuring effective ventilation and low humidity can deter corrosion in power generators.

Functional Tests: Periodic functional tests of components also constitute crucial maintenance routines. Regular functioning helps in identifying potential issues early and allows for timely remedial action.

The role of pro-active, detailed routine maintenance in preventing corrosion in power generators is invaluable. A well-drawn, regular maintenance plan is arguably the single most effective strategy in prolonging the service life of power generators, ensuring they continue to operate efficiently and reliably.

Corrosion Inhibitors

Corrosion inhibitors play an integral and highly effective role in mitigating corrosion in power generators. These distinctive substances restrict the chemical reactions that instigate corrosion, displaying the prowess to substantially prolong the lifespan of both marine and non-marine power generators.

At their core, corrosion inhibitors work by forming a passive layer atop the exposed metallic surfaces. This protective film serves as a substantial barrier, warding off the electrolytic environment that catalyzes the corrosion process.

There are, broadly, three types of corrosion inhibitors: anodic, cathodic, and mixed-type inhibitors.

Anodic inhibitors work by making the metal surface more anodic, often by promoting the formation of a protective oxide layer.

Cathodic inhibitors slow down the cathodic reaction, indirectly protecting the metal against corrosion.

Mixed-type inhibitors function by inhibiting both the anodic and cathodic reactions.

Their application is both practical and feasible. Routinely spraying or brushing the inhibitors onto the generator’s surface forms part of the regular maintenance and can vastly decline the rate of corrosion in power generators.

However, their employment necessitates expert discretion. The choice of a suitable inhibitor hinges upon several factors—the nature of the metal, the operating environment, and the conditions to which the generator is exposed.

Moreover, it’s noteworthy that the employed inhibitors should be environmentally friendly, particularly for marine power generators. The persistent concern for marine pollution requires the selection of inhibitors that do not harm the marine eco-system.

In marine environments, where the constant exposure to salt water considerably accelerifies corrosion, inhibitors can crucially stave off the corrosive damage. Similarly, in non-marine settings, corrosion inhibitors can significantly curb the covert and often unnoticed progression of corrosion.

The judicious use of corrosion inhibitors is an efficient strategy towards curbing corrosion in power generators. Their routine implication as part of a well-rounded maintenance plan can significantly uphold the structural integrity of power generators, enhancing their performance, efficiency, and service life.

The Role of Dehumidifiers in Corrosion Prevention

In the management of corrosion in power generators, particularly those in non-marine settings, dehumidifiers play a pivotal – often overlooked – role. This innovative method primarily works by reducing the ambient humidity level around the generator, curtailing the electrochemical process that facilitates corrosion.

The principle behind using dehumidifiers is tied to the fundamental understanding of corrosion. For corrosion to occur, an electrolyte, such as water, is required to form a conductive path between the anode and cathode on the metal component. By decreasing the humidity level in the environment of the generator, dehumidifiers effectively reduce the amount of available water vapor that can condense on the unit, hindering the corrosion-causing electrochemical reaction.

To quantify, when the relative humidity falls beneath 60%, the rate of corrosion in power generators tends to slow down significantly. For optimal results, the aim should be to maintain the relative humidity between 40-50%. A dehumidifier makes achieving this feasible, providing a cost-affordable and efficient means to combat corrosion, extending the machinery’s lifespan.

Moreover, dehumidifiers are invaluable assets to generators housed in enclosed spaces, such as shipping containers or generator rooms where airflow may be restricted, and the potential for condensation is high. It’s crucial these spaces are adequately dry to prevent any unnecessary and disruptive downtime due to corrosion-related failures.

However, merely using a dehumidifier should not eclipse the importance of other mitigation strategies. It should work in conjunction with regular mechanical inspections, appropriate material selection, adequate protective coatings, and consistent cleaning routines.

Dehumidifiers can add a decisive layer of protection to non-marine power generators, securing them from the detrimental effects of corrosion. By keeping the humidity in check, dehumidifiers play a formidable role in offenses against corrosion in power generators, ensuring that the equipment operates at peak efficiency, with extended operational longevity.

Understanding the detailed causes of corrosion in power generators is imperative for engineers and maintenance teams. Implementing preventive measures becomes paramount to mitigate the pervasive impact of corrosion and uphold the integrity of power generation infrastructure.

We hope that this article has been useful to you to contribute to the proper maintenance of your energy generation infrastructure.

Don’t hesitate to reach out for any further information or assistance regarding to prevent corrosion in power generating equipment. Contact us at the phone number +1.954.657.7777, or write to us at info@bnhgenerators.com, and we will gladly help you.