Uninterrupted power supply holds paramount importance in the manufacturing industry. Any power outage can result in significant financial losses due to halted production, damaged equipment, and missed deadlines. However, with the advent of industrial generator sets, manufacturers now have a reliable solution to combat power disruptions. In this article, we delve into the world of industrial generator sets and explore their role in providing backup power for manufacturing facilities.

Manufacturing facilities often experience varying power demands depending on their production processes. Equipment such as large motors, conveyors, and refrigeration systems can lead to sudden, sharp spikes in electricity consumption. Consequently, even a momentary power interruption could lead to severe consequences such as broken production lines or damaged materials. By comprehending the power needs of the manufacturing industry, we can better appreciate the importance of industrial generator sets as a backup power solution.

To tackle the challenges posed by power outages, it is crucial to understand their nature and causes. Power outages occur when there is an interruption in the supply of electricity to a manufacturing facility. These interruptions can be caused by various factors such as severe weather conditions, equipment failures, utility issues, or even human errors. The impact of power outages on manufacturing operations can be detrimental, ranging from halted production lines to damaged machinery and lost revenue.

Minimizing downtime and financial losses during power outages requires the implementation of effective backup power systems and emergency response plans. One solution is the installation of industrial generator sets that can quickly provide electricity to critical machinery and processes.

Emergency response plans should identify critical machinery and processes, prioritizing power restoration efforts to minimize downtime and ensure a swift recovery.

Introduction to Industrial Generator Sets

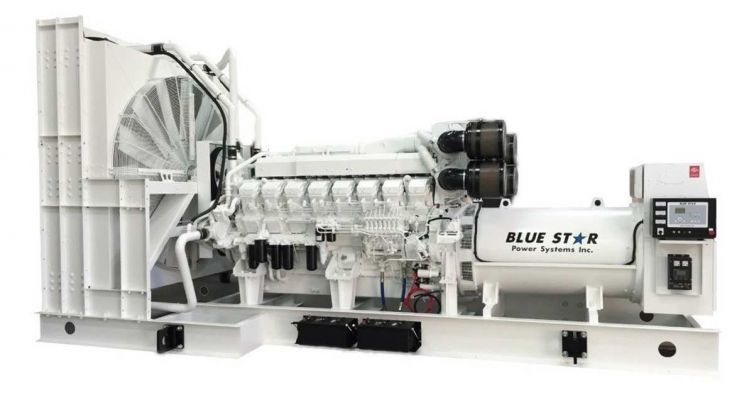

Industrial generator sets, commonly known as gensets, are robust power generation systems specifically designed for industrial applications. These gensets come in various sizes and configurations to cater to the diverse power requirements of different manufacturing facilities. They are equipped with powerful engines and alternators to produce electricity and ensure uninterrupted power supply during outages.

In today’s world, industrial generator sets play a vital role in powering various industries, serving as reliable sources of backup and prime power. These generator sets are specifically designed to meet the unique power requirements of industrial applications.

Available ex factory. (Call to confirm)

Available ex factory. (Call to confirm)

Available ex factory. (Call to confirm)

Available ex factory. (Call to confirm)

Available ex factory. (Call to confirm)

Available ex factory. (Call to confirm)

Available ex factory. (Call to confirm)

Available ex factory. (Call to confirm)

Types of Industrial Generator Sets

1. Diesel industrial generator sets:

Diesel generator sets are widely used in industrial settings, thanks to their efficient performance and durability. These generator sets utilize diesel fuel as their primary source of energy. Diesel, a hydrocarbon-based fuel, offers several advantages such as high energy density and better fuel efficiency compared to gasoline. Additionally, diesel generators exhibit excellent load acceptance and are known for their longevity. However, they do produce more emissions and require regular maintenance.

2. Natural gas industrial generator sets:

Natural gas generator sets harness the power of natural gas, a clean-burning fossil fuel, to generate electricity. Natural gas is composed primarily of methane and is sourced from underground reservoirs. One of the major advantages of natural gas generators is their lower emission levels, making them an environmentally friendly option. They also operate quietly and have lower maintenance requirements. However, the availability of natural gas infrastructure can limit their applicability.

3. Biogas generator sets:

Biogas generator sets are gaining popularity due to their sustainable nature. Biogas, a renewable energy source, is produced through the decomposition of organic waste materials such as agricultural waste, food waste, and wastewater. These generator sets utilize biogas as a fuel source, making them environmentally friendly and helping reduce greenhouse gas emissions. Biogas generator sets are versatile and can be used in various industries, including agriculture and wastewater treatment plants, where ample organic waste is available.

Factors to Consider when Choosing an Industrial Generator Set

When selecting an industrial generator set, several factors must be taken into consideration to ensure the best fit for a manufacturing facility.

Firstly, the power capacity requirements must align with the facility’s electricity demands to avoid overloading or underutilization.

Additionally, the choice of fuel type, such as diesel, natural gas, or propane, must be evaluated based on factors like availability, cost, and environmental impact.

Efficiency and environmental considerations should also be weighed, as modern gensets often come with advanced features to minimize emissions and maximize energy efficiency.

Noise levels are another crucial aspect, especially in noise-sensitive manufacturing environments.

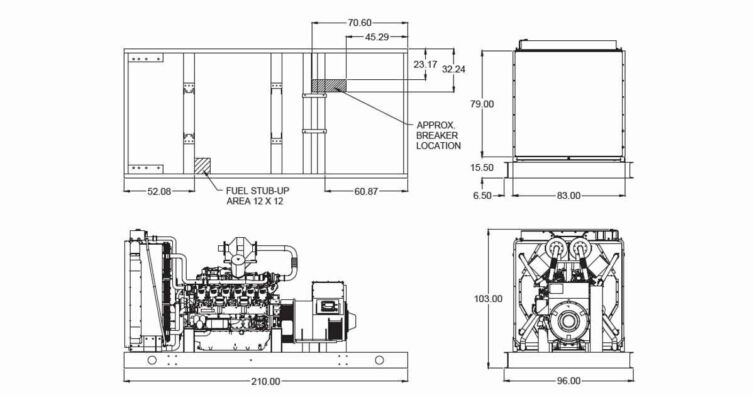

Finally, the size and portability of the generator set should be accounted for to ensure seamless integration into the facility.

Available ex factory. (Call to confirm)

Available ex factory. (Call to confirm)

Available ex factory. (Call to confirm)

Available ex factory. (Call to confirm)

Available ex factory. (Call to confirm)

Available ex factory. (Call to confirm)

Available ex factory. (Call to confirm)

Available ex factory. (Call to confirm)

Integrating Industrial Generator Sets with Manufacturing Facilities

Proper integration of industrial generator sets within manufacturing facilities is vital for their optimal performance. Selecting an appropriate location for the generator set is crucial to ensure easy access for maintenance and minimize noise or exhaust-related disturbances. An efficient transfer switch is essential to transition smoothly from grid power to generator power during outages. Furthermore, compatibility with existing electrical systems should be considered to avoid any issues during the power transfer process.

1. Sizing and Capacity of Industrial Generator Sets

A. Determining power requirements:

Before selecting an industrial generator set, it is essential to accurately determine the power requirements of the intended application. Factors such as the types of equipment, their power ratings, and the starting currents are considered. A thorough load analysis and assessment of the power factor are crucial to ensure that the generator set can handle the electrical load without overloading or underperforming.

B. Understanding power factor and its impact on generator sizing:

Power factor is a measure of how effectively electrical power is being utilized. It signifies the ratio of real power (useful power) to apparent power (total power). A power factor of 1 indicates optimal power utilization, while a power factor less than 1 indicates reactive power consumption. Industrial generator sets should be sized considering the power factor, as a low power factor can lead to inefficiencies and potential damage to the generator set. Adjusting the generator capacity based on the power factor ensures optimum performance and efficiency.

2. Maintenance and Care for Industrial Generator Sets

To maintain the reliability and longevity of industrial generator sets, regular servicing and inspection are imperative. Fluid checks and replacements, such as oil and coolant, should be performed at recommended intervals to ensure optimal performance. Load testing procedures should also be implemented periodically to evaluate the generator set’s ability to handle the facility’s power demands during an outage. By adhering to a proactive maintenance schedule, manufacturing facilities can avoid unexpected breakdowns and ensure their generator sets are always ready to provide backup power.

Environmental Considerations

A. Emissions control and regulations:

Industrial generator sets contribute to air quality concerns due to the emissions produced during their operation. Emission control regulations are in place to limit the release of pollutants such as nitrogen oxides (NOx), sulfur oxides (SOx), particulate matter, and carbon monoxide (CO). Generator manufacturers are continuously developing technologies and solutions to meet these regulations, including advanced exhaust treatment systems and catalytic converters. Choosing generator sets that comply with emission standards helps minimize their environmental impact.

B. Noise pollution and mitigation measures:

Generator sets, especially those operating in noise-sensitive areas, can contribute to noise pollution. Noise from generator sets can disturb communities and have negative impacts on human health. To address this, manufacturers integrate noise mitigation measures into the design of generator sets, such as soundproof enclosures, exhaust silencers, and vibration isolation systems. These measures help reduce noise levels, making generator sets more suitable for urban and noise-sensitive environments.

Advantages of Industrial Generator Sets for Manufacturing

The integration of industrial generator sets into manufacturing facilities brings numerous advantages.

Firstly, the ability to mitigate production loss during power outages is invaluable. Even a short interruption in power can disrupt entire production lines, resulting in financial losses and missed deadlines. With a reliable backup power source, manufacturing facilities can continue their operations seamlessly during outages, reducing downtime and preventing costly setbacks.

Additionally, industrial generator sets safeguard machinery and equipment from power surges that may occur when grid power is restored. This protection ensures the longevity and optimal functioning of critical manufacturing equipment.

Case study: Successful implementation of Industrial Generator Sets in Manufacturing

Manufacturing Company “XYZ”.

(“XYZ” is a client of Brags & Hayes generators that we have kept anonymous since his name does not add value to inform about the concept discussed in this article).

XYZ Manufacturing Company faced many critical power outage incident that halted their production lines, each for several hours, due to a significant deterioration of the quality of service of the electrical network in the area where your factory is located.

They were investigating the causes of the deterioration of the electrical network service in the area and they realized that it was a situation that was beyond their area of influence and even the authorities informed them that the problem was also beyond their area of management.

Determined to find a solution to avoid such disruptions in the future, they invested in an industrial generator set which they bought from Brags & Hayes generators, together with the installation and maintenance service

By installing a generator set with the appropriate power capacity, they ensured uninterrupted power supply during subsequent outages. This decision proved beneficial as they experienced improved production continuity and significant cost savings.

The investment in the generator set paid off, as XYZ Manufacturing Company no longer had to bear the financial burden of prolonged downtime.

Finally, the purchase of their industrial generator paid for itself because they no longer lost money due to the stoppage of the factory.

Future Trends and Innovations in Industrial Generator Sets

The world of industrial generator sets is continuously evolving to meet the changing needs of manufacturing facilities.

Some of the exciting trends and innovations we can expect in the future include the integration of renewable energy sources. Manufacturers are exploring ways to incorporate renewable sources such as solar and wind power into generator sets, reducing reliance on fossil fuels and promoting sustainability.

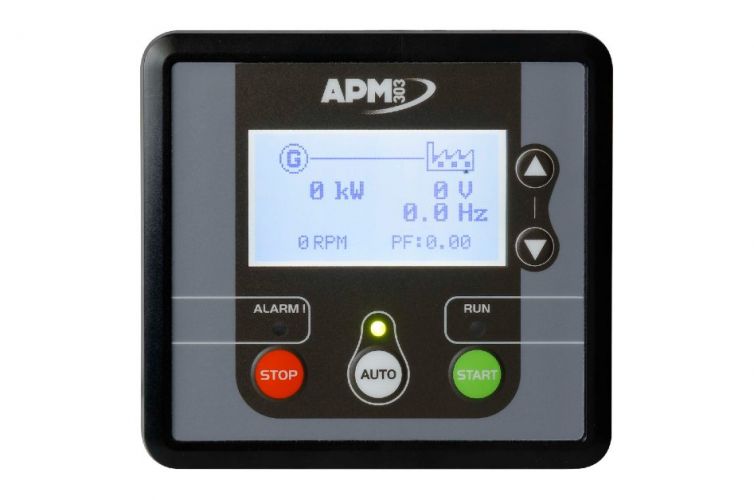

Additionally, advanced monitoring and remote control capabilities are becoming more prevalent, allowing facility managers to monitor and control their generator sets from anywhere, ensuring optimal performance and efficient power management.

The industry is also focusing on improving fuel efficiency and reducing emissions, with manufacturers developing more eco-friendly generator sets to minimize environmental impact while providing reliable backup power.

Industrial generator sets play a crucial role in ensuring uninterrupted power supply for manufacturing facilities. By understanding the power needs of the industry and choosing the right generator set, manufacturers can protect their operations from disruptions and costly downtime. Proper integration, maintenance, and care of these generator sets are essential to maximize their performance and longevity. Through real-world case studies, we have witnessed the positive impact of industrial generator sets in enabling seamless manufacturing operations. Reputable manufacturers and providers offer a wide range of options and solutions to cater to different facility needs. As the industry continues to evolve, we can expect further advancements, including the integration of renewable energy sources and enhanced monitoring capabilities. Investing in quality industrial generator sets is a wise decision for manufacturing facilities, ensuring they have a reliable backup power solution to safeguard their operations and prevent financial losses.

Don’t hesitate to reach out for any further information or assistance regarding industrial generator sets requirements. Contact us at the phone number +1.954.657.7777, or write to us at info@bnhgenerators.com, and we will gladly help you.