In an era marked by the global transition to renewable energy sources, a definitive trailblazer has emerged: Battery Energy Storage Systems. These harbingers of technological progress enable us to store valuable power generated from power sources for later use, thereby bolstering the grid’s efficiency.

Critical infrastructure facilities today grapple with issues like power outages, brief non-compliance of utility frequency or voltage, and skyrocketing utility bills. With the rapid progression of technology, new solutions have emerged. Battery energy storage systems stand out as a promising solution to reduce utility costs and swiftly address power stabilization issues. Such systems are increasingly garnering attention, particularly in light of the Inflation Reduction Act (IRA) passed by the U.S. government. This act encourages both the manufacture of battery storage components and their installation. Battery energy storage systems consumers primarily fall into three categories: residential, utility, and commercial/industrial. In this post we will concentrate on commercial/industrial consumers and applications.

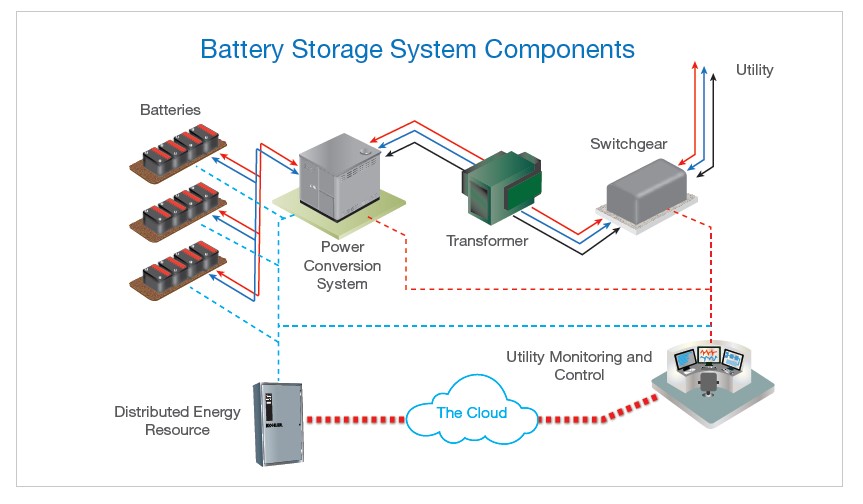

BATTERY STORAGE SYSTEM COMPONENTS

Battery energy storage systems are dynamic mechanisms that transform stored DC (direct current) energy into usable AC (alternating current) power. A multitude of components collaborate meticulously to preserve conditions for battery operation, power conversion and system control, which is responsible for synchronizing the battery’s charging and discharging processes. Major system components are discussed in the subsequent section.

ENCLOSURE

The enclosure of battery energy storage systems plays a key role within a battery storage system, safeguarding the batteries.

Two central forms of protection can be found. The first is exclusion of wildlife, while the second involves management of the cooling system’s temperature. Optimum performance mandates temperature maintenance within specific limits for the batteries.

Another important function of the enclosure relates to safety. The occurrences of thermal events, characterized by internal shorts in battery cells, can result in battery fires and even cause it to spread to other batteries. If left unchecked, the entire system can be engulfed in flames. Although battery manufacturers design batteries with numerous safety redundancies to mitigate thermal runaway, the risk cannot be completely eradicated. The enclosure’s final safety element is a fire suppression system, which is triggered based on temperature or gas detection within the enclosure.

DC BUS INTERCONNECTIVITY

A key design element for battery energy storage systems utilizing multiple battery enclosures is the interlinking of the DC bus from one section to another. This is crucial to abbreviate the system’s setup time and consequently, pare down the overall installation expense.

The battery racks housed within the enclosures establish a connection starting from the terminals of the battery management system (BMS) to the DC bus encapsulated within the enclosure.

Advancements in enclosure design now incorporate external DC bus links from either side, serving to expedite the installation process.

THERMAL MANAGEMENT OF LITHIUM-ION BATTERIES

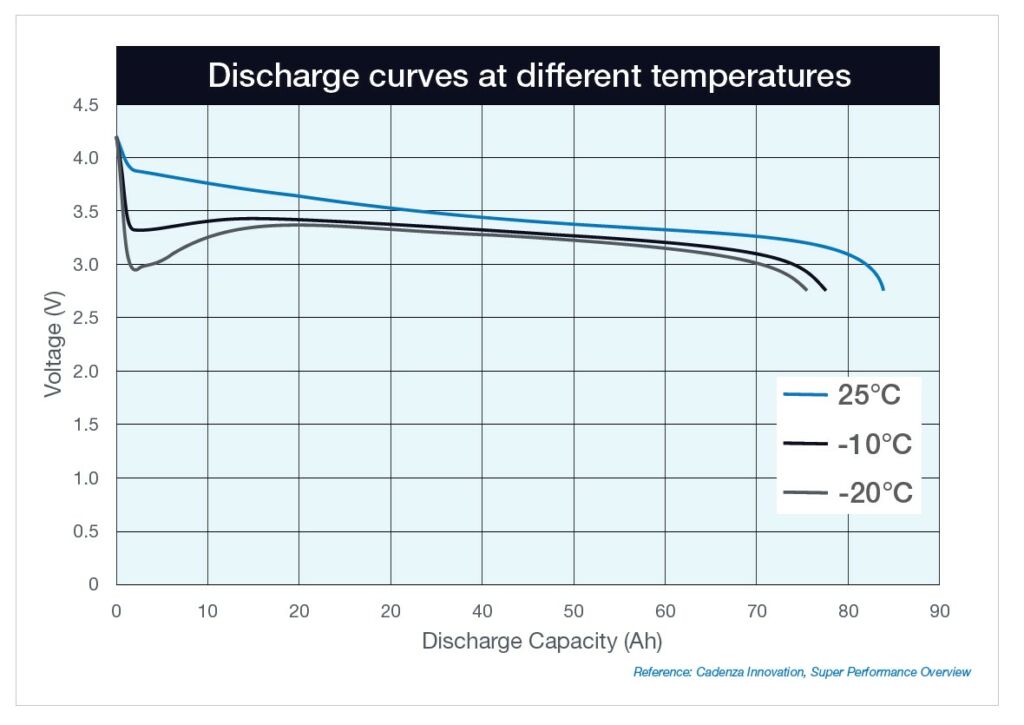

A cardinal feature within a battery energy storage systems is its ability to cool effectively. Producers of lithium-ion batteries advise keeping the battery’s temperature at a steady 23°C, with a permissible variance of +/- 2 degrees. Any temperature deviations can significantly influence the battery’s functioning and lifespan.

Falling temperatures under the 23-degree mark impair the batteries’ discharge capacity.

TWO COOLING SYSTEM TYPES

Cooling systems predominantly fall into two categories: forced-air and liquid cooling.

1. Forced-air cooling.

Forced-air cooling was the go-to solution in the initial stages of battery storage designs due to its economical cost and straightforward design. It performed reasonably well in maintaining the suggested battery temperatures. Yet as these early systems began showing signs of age, a gradual decline in battery performance was apparent.

To combat this downturn in performance and extend battery lifespan, storage system providers turned to the development of liquid-cooling technology. Owing to its closer proximity to the batteries, this technology has proven more effective in cooling batteries.

2. Liquid-cooling technology.

Now the preferred cooling mechanism in the industry, liquid-cooling technology uses glycol as the cooling medium. It has the perk of durability with a lifespan of up to a decade without requiring a replacement. As part of the operation and maintenance process, annual measurement of the glycol level is recommended.

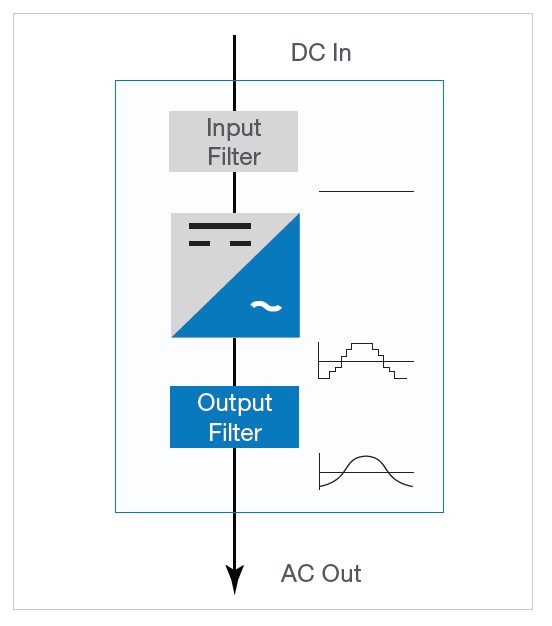

INVERTER

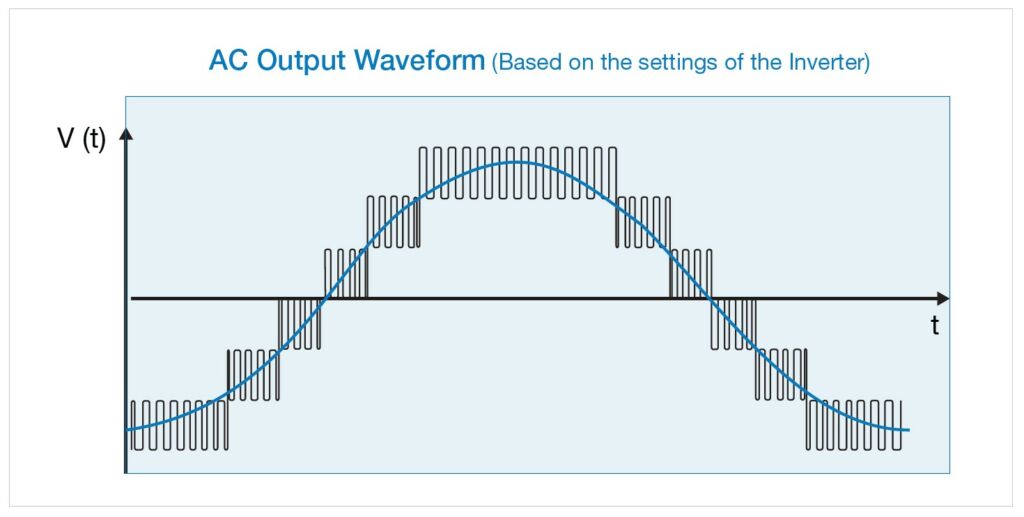

At the heart of a battery energy storage systems lies the inverter, a critical component responsible for transforming stored DC energy into AC power. The conversion transpires through the action of turning transistors on and off to generate an AC waveform-a process known as pulse-width modulation (PWM).

Usually located outside the battery storage enclosure, the inverter connects with the battery output from the battery management system (BMS) at the inverter’s input (DC In), depicted in Figure 3.

Inverters operate in two distinctive modes – grid-following and grid-forming.

In grid-following mode, the inverter aligns its output with the AC reference signal input, typically sourced from the utility.

In contrast, grid-forming mode enables the inverter to produce the AC output waveform in line with the inverter’s settings. This mode comes into play in the absence of the AC reference signal input.

TRANSFORMER

In medium voltage applications, transformers are a necessity. They are employed to escalate the voltage in order to accommodate the specifications of the client’s power system.

While not an obligation for low voltage scenarios, transformers present an excellent choice for interconnection points between the two power systems. They possess the advantage of preventing faults from spreading. Additionally, they offer a method for purifying the power, although this benefit does come with added expenses. The output from the inverter would establish a connection to the transformer.

CONTROL SEGMENT: AN ENERGY MANAGEMENT SYSTEM HUB

The control section operates as the central nexus for energy management system elements, facilitating the transmission of battery information to the cloud for advanced processing or generating reports. Key components within the control section may include:

- Cellular Router: This component is entrusted with the job of relaying the data collected from the energy-management system to the cloud. Here, the energy-management software developers can utilize the data to create reports or implement system use cases.

- Energy-Management Hardware: This piece of hardware is tasked with carrying out the use cases designed by the system.

- Power Meter: This device aids in comprehending the amount of power that the battery storage system is exporting during the execution of system use cases.

- Network Switch: This tool ensures communication continuity among devices in the system, using varied protocols such as Modbus or CAN.

BATTERY STORAGE SYSTEM: EXAMINING POTENTIAL USE CASES

ASPECTS OF PURCHASE CONSIDERATIONS

When deciding to invest in a battery energy storage systems, customers typically look at a range of factors including financial viability, power resiliency, shifting energy sources, and the desire to decrease carbon emissions.

FINANCIAL ASPECTS AS DECISION DRIVERS

Despite the array of factors that contribute to the decision-making process for battery energy storage systems, the primary influencer tends to be the financial perspective. To justify the investment, each potential use case should be explored, even if not all of them will be deployed in practice.

System designers collaborate with customers to maximize financial advantages, often through utility bill reduction and minimizing downtime due to utility failures. Chosen use cases significantly influence battery design, which needs to be optimized for either high power output or sustained power supply. Balancing power and long duration capabilities can add significant costs, so defining system use cases is crucial.

PRINCIPAL USE CASES FOR COMMERCIAL/INDUSTRIAL CUSTOMERS

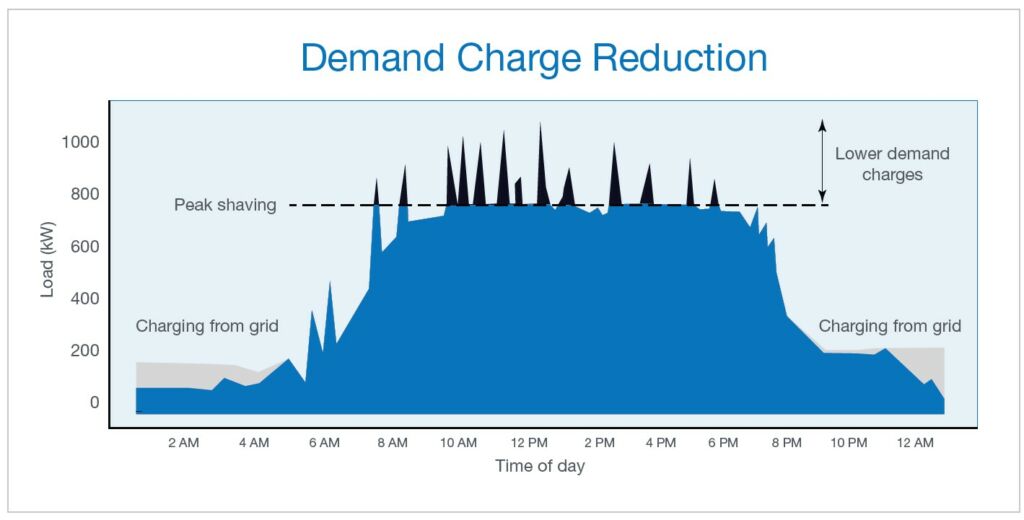

DEMAND CHARGE REDUCTION

Demand charges, added onto monthly utility bills, serve to fund infrastructure maintenance. Calculated by multiplying the client’s highest monthly kilowatt consumption by a utility-defined multiplier, reductions in demand charges can create substantial savings. Ideal for large load profile customers with high-demand charge multipliers, developers usually aim for savings between 30%-50% of the total utility bill.

DEMAND RESPONSE

Utility companies often run programs requesting customers to temporarily disconnect from utility power. Such a switch can be automated or manually done following a telephone request. Once asked to switch over, customers must rely on alternative power sources like generators or batteries, requiring careful sizing of batteries to cover load demand for the expected period.

FREQUENCY REGULATION / VOLTAGE RESPONSE

In these use cases, the battery storage system steps up to maintain bus voltage and frequency within acceptable limits, thus avoiding critical load trips. Here, the battery system supplements real power during frequency dips to secure 60Hz operation or manage the rated system voltage by dispensing or absorbing reactive power.

PV SELF-CONSUMPTION

Complementing each other perfectly like classic duos, solar energy and batteries are a natural pair. The variability of solar energy can be balanced with batteries, offering customers an on-demand renewable resource.

BACKUP POWER

In case of power failure, customers can rely on batteries to supply power to essential loads based on agreed duration, typically ranging from two to four hours.

Battery energy storage systems are particularly suitable for customers grappling with fluctuating utility rates, notable load peaks leading to high-demand charges, or those situated in regions without a stable utility power supply. These systems, coupled with generators, are essential in ensuring energy resilience for customers.

As prices continue on a downward trend and new technologies start to surface, it’s anticipated that critical infrastructure facilities will increasingly transform to mirror microgrids.

Don’t hesitate to reach out for any further information or assistance regarding to Battery Energy Storage Systems. Contact us at the phone number +1.954.657.7777, or write to us at info@bnhgenerators.com, and we will gladly help you.