In today’s world, where uninterrupted power supply is essential for both residential and commercial settings, having a reliable standby generator is paramount. It is important to understand the implications of correctly installing an energy generator. For this reason, we document a case study below.

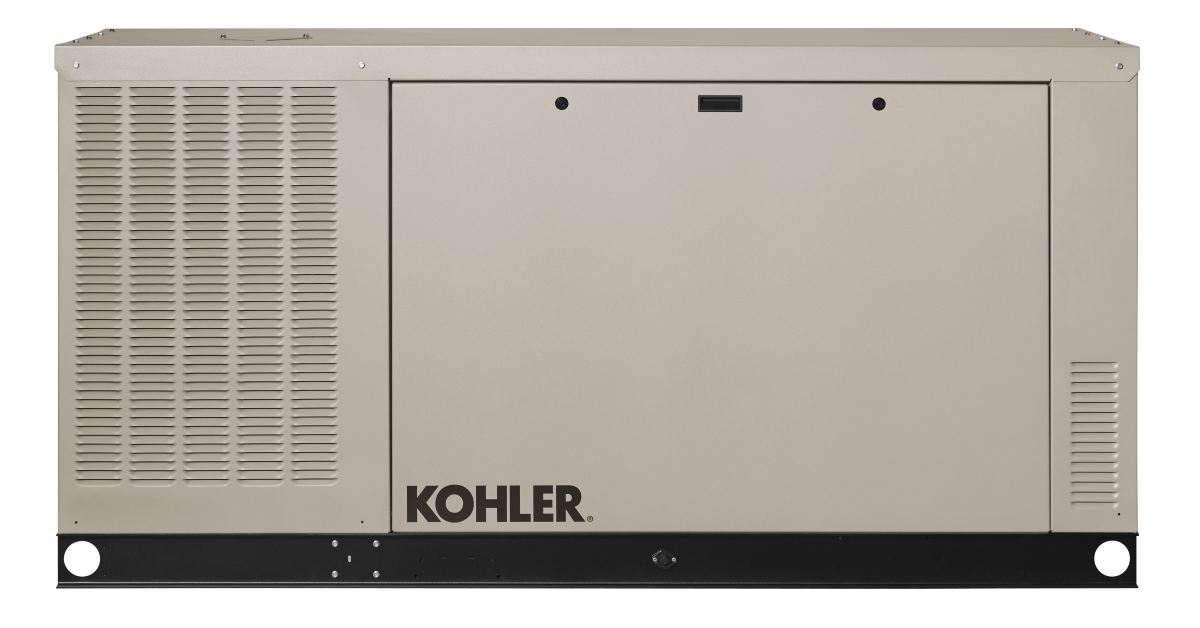

In this case study, we delve into the meticulous process of installing the KOHLER home generator solution, Residential Gas (LPG/Natural Gas) Generator Set Model 60RCLB-QS1 1-240V 59 kW LPG / 57 kW NG 1 Phase, 240V, with aluminum Enclosure in Fort Lauderdale, Florida (new customer´s house), a powerhouse that ensures Brags & Hayes customer´s home remains lit and functional even during power outages.

Let’s explore the step-by-step journey of installing this technological marvel.

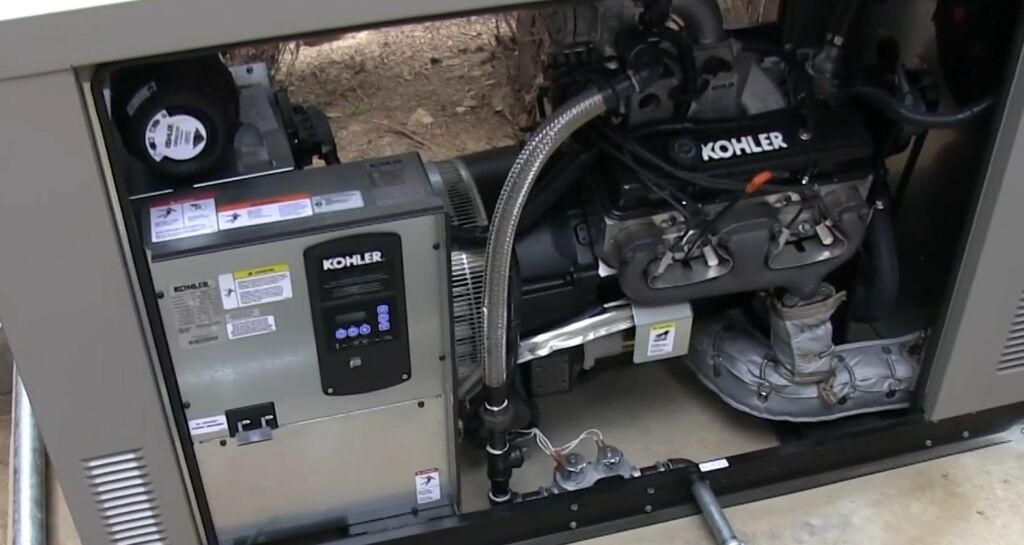

The KOHLER 60KW, 1-PHASE HOME STANDBY GENERATOR is a high-capacity home generator solution, single-phase, LIQUID-COOLED, standby generator designed to provide seamless backup power to homes and small businesses. With its robust build and cutting-edge technology, it offers reliable power generation during emergencies.

Standard Features: UL2200/CSA, 60 Hz, Aluminum Sound Shield, Unit Mounted Radiator, Standard Air Intake, RDC2 Controller which includes a 2.5AMP Battery Charger, Flexible Fuel Lines, Coolant in generator, 45 C Cooling System and 5-Year Basic Warranty, OnCue Plus.

Reliable power for large residential or small business needs. When the power goes out during a bad storm or power failure, your 60 kW KOHLER® generator with industrial-grade engine keeps your home or business – from central air to sump pump to personal computers – up and running (Based on generator and load size).

Powerful: In just 10 seconds, your KOHLER generator automatically restores power and keeps you connected to the things you love to do.

- Smart: You get steady, high-quality power that protects your electronics from damage related to low-quality power sources.

- Premium warranty: We’ve got you covered with 5-year, 2,000-hour protection, and an aluminum enclosure that’s built to last.

- Quiet: Neighborhood-friendly, with weekly exercise volume that’s similar to a normal conversation.

- Innovative: This generator’s patent-pending innovations include a three-fan, automotive-style cooling system that keeps the sound level down.

Importance of a Reliable Standby Generator for this home generator solution

Power outages can disrupt daily life and pose risks to safety, especially in extreme weather conditions. A standby generator like Generator Set Model 60RCLB-QS1 ensures continuity in critical operations, safeguards sensitive equipment, and enhances overall comfort during power interruptions.

Purpose of this Case Study

This case study aims to provide a comprehensive guide to installing the KOHLER home generator solution, 60KW, 1-PHASE HOME STANDBY GENERATOR. From pre-installation preparations to post-installation maintenance, we will explore every aspect to help you make informed decisions and ensure a trouble-free installation process.

Pre-Installation Preparations

Installation site assessment and Selection.

Evaluating Power Requirements.

Before installing this home generator solution, it’s crucial to assess your power needs accurately. This involves calculating the electrical load your home or business requires during an outage to ensure the generator is appropriately sized. Generator sizing relies on load calculations that consider the total power demand of appliances and systems. Precision is key to selecting the right capacity.

In the specific case of our client’s requirements (for a new house), the projected consumption of the devices that will be included in the house’s equipment was calculated. Additionally, a security margin was added to account for future load expansions and to accommodate transient load regimes.

Local Building Codes and Permits.

Familiarize yourself with local building codes and permit requirements for generator installations. Compliance is essential to avoid legal complications and ensure safety.

In this specific case, the building codes and permit requirements for generator installations in Fort Lauderdale, Florida are as follows:

- Permit Application: As of February 8, 2021, the City no longer accepts permit applications via email. New submissions must now be either digital OR paper.

- Building Code Compliance: Generator installation must comply with the Florida Building Code, National Electrical Code, Florida Fuel Gas Code, Florida Fire Prevention Code, and the National Fire Protection Association Code (NFPA).

- Generator Location: Generators must be installed no closer than 5 feet from building openings (doors and windows). The location of the generator shall conform to local Zoning requirements and shall be mounted above the base flood level.

- Generator Details: Provide information for the generator showing KW rating, ampacity, voltage, phase, fuel source and dimensioning. All loads connected to generator shall be identified. Provide load calculations for the generator.

- Transfer Switch: Required for all generators and shall be rated for the connected load.

- Signage: A permanent sign shall be placed at the electrical service entrance equipment that indicates the location of on-site optional standby power sources.

Please note that this is a general guide and specific requirements may vary. For the most accurate information, it’s recommended to contact the local building department.

Fuel Supply Infrastructure.

It is very important to ensure that there is a reliable power source at the installation site (well installed according to the standard).

In the specific case of the generator KOHLER 60RCLB-QS1, LPG or Natural Gas. Yes, this Kohler generator is compatible with both.

The LPG is short for liquefied petroleum gas which is either propane or butane with a heat content of 93.2MJ/m3. Natural gas is however primarily methane and has a heat content of 38.7MJ/M3. Natural gas is delivered to homes via gas pipelines underground. In this specific installation case the fuel supply was a natural gas service point.

Ensure your chosen fuel source has a reliable supply infrastructure in place to sustain continuous generator operation.

Generator Placement.

Related to generator placement, for this project was take in to account several factors:

- Foundation and anchoring: We made sure that in the construction project there were a stable and secure foundation for the generator. Follow the manufacturer’s guidelines for foundation requirements, which typically involve a concrete pad or slab that is level and capable of supporting the weight of the generator.

- Securing the generator: To prevent movement or potential damage during operation, we assure that the generator should be securely fastened to its foundation. In this point is important that you in your generator project always follow the manufacturer’s instructions for anchoring methods, which may include using bolts and brackets to ensure stability.

- Ventilation and exhaust considerations: We assure the adequate ventilation for the safe operation of a generator. This allows for proper airflow around the unit. Always avoid placing the generator in enclosed or tight spaces that could impede the flow of air. We assure in this installation the proper exhaust routing for safety and to prevent the buildup of harmful fumes. It is essential to direct the generator’s exhaust away from windows, doors, and other openings where exhaust gases could enter the building. The manufacturer provide specific instructions on exhaust routing, including if its needed the use of approved exhaust pipes and the recommended distance from nearby structures.

- Proper airflow for cooling: We assure the adequate airflow necessary to keep the generator cool during operation. The manufacturer typically provide guidelines on the required clearances around the unit to ensure proper ventilation. In your generator´s installation always be sure to follow these recommendations to prevent overheating and ensure the generator operates efficiently.

Please note that while these guidelines provide in this case study are general recommendations, it’s always best to consult the manufacturer’s installation manual and local building codes for specific requirements and regulations pertaining to your location.

Electrical connections of the Kohler 60KW home generator

Transfer switch installation.

A transfer switch is a critical component for connecting the generator to the home’s electrical system. It allows for the safe and automatic transfer of power between the utility power and the generator power.

In this project we installed the ATS 400 AMPS, 1 PHASE, 60HZ, 3 wire, 2 pole, 240v, Aluminum Enclosure NEMA 3R OUTDOOR, RXT-JFNC-400A SEQS4.

This ATS have the following features:

- Designed for use only with KOHLER generators equipped with RDC2 or DC2 controls.

- Installs indoors or outdoors.

- Service Entrance (Utility Disconnect).

- Includes RXT single phase combined interface/load management board.

- Optional external LED display or optional external LED display with load management.

- Corrosion-resistant aluminum enclosure.

- 5-year, 2000-hour limited warranty.

- Volts: 240 V (single-phase).

- Poles: 2 (single-phase).

Wiring and control panel integration.

The wiring between the generator and the transfer switch was be properly sized and installed to handle the electrical load. The control panel of the generator was also integrated with the transfer switch to enable automatic switching and monitoring of the generator’s status.

Generator grounding.

As proper grounding is essential for electrical safety. The generator was grounded according to the manufacturer’s instructions and local electrical codes.

At this point it is neccesary to highlight that it is important to comply with local electrical codes and regulations for generator grounding to ensure a safe and compliant installation. These codes may specify the specific grounding requirements for generators, such as the size of grounding conductors, the number of grounding electrodes, and the method of connection.

Compliance with electrical codes.

We make sure that the installation compliance with electrical codes for the safe and legal installation of the Kohler 60KW home generator. This includes adherence to all relevant national, state, and local electrical codes and regulations. These codes cover various aspects of generator installation, including wiring, grounding, clearances, and electrical safety measures. This ensure proper compliance throughout the installation process.

It is important to note that specific requirements and regulations may vary depending on your location. Therefore, it is essential that you in your installation consult the generator manufacturer’s installation manual, as well as local electrical codes and regulations, to ensure that all electrical connections, transfer switch installation, wiring, control panel integration, and generator grounding are performed correctly, safely, and in compliance with applicable codes and regulations.

System Checks. Initial Startup and Load Tests

System checks.

Initial startup and load tests for this home generator solution. Once the generator is installed and connected to the electrical system, the initial startup test is conducted. This involves starting the generator and checking that it is running smoothly, without any unusual noises or issues. Additionally, load tests are performed to ensure that the generator can handle the expected electrical load.

Functionality verification.

All components of the generator system, including the transfer switch, control panel, and integrated monitoring systems, was tested to verify their proper functioning. This included checking for correct operation of automatic transfer of power between the utility and generator, monitoring of generator status and power output, and all integrated functionalities.

Simulating power outage scenarios.

Transition to generator power: To simulate a power outage scenario, the utility power was intentionally disconnected. This triggered the automatic transfer switch to activate and switch the electrical load to generator power. This transition was swift and seamless, allowing for uninterrupted power supply to essential circuits or the whole house.

Monitoring performance and load balancing.

During the simulated power outage, the generator’s performance was closely monitored. This included checking the generator’s power output, voltage and frequency stability, and fuel consumption. Load balancing was carefully managed to ensure the generator is not overloaded and sustained the anticipated electrical load without issues.

In addition to these specific tests, we keep a record of the testing and commissioning process, including all test results, inspections, and any adjustments made during the installation process. This documentation will help ensure that the generator system has been properly tested, commissioned, and is in compliance with manufacturer specifications and applicable codes.

Don’t hesitate to reach out for any further information or assistance regarding to generators installation. Contact us at the phone number +1.954.657.7777, or write to us at info@bnhgenerators.com, and we will gladly help you.