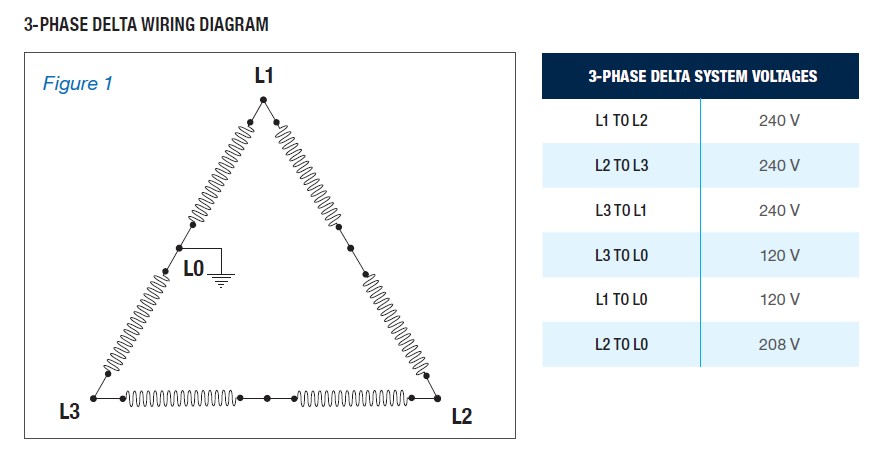

For electrical engineers working with three-phase systems, it is common practice to postulate that loads will distribute evenly across the system coils, similar to what Figure 1 exemplifies. Yet, contrary to theoretical assumptions, real-life applications frequently present us with systems featuring unbalanced loads. One glaring example is the 120/240-volt three-phase delta system, frequently used for a mix of 120-volt and 240-volt single-phase loads as well as 240-volt three-phase loads. In essence, unbalance is the backbone of such systems, evidenced in instances such as a supermarket equipped with single-phase LED lighting and cash registers, and three-phase refrigeration and freezer motors.

Adding novelty to complex systems nowadays is the integration of motion-sensor-controlled lighting, which introduces another factor to consider in the balancing act of residual loads.

Ideally, generator manufacturers would avoid utilizing such unbalanced systems. However, circumstances often require us to provide standby power to pre-existing load configurations of this nature.

For system designers connecting their loads to utilities, it’s a straightforward task selecting separate single-phase transformers for each of the three phases. Conversely, supplying standby power for such systems poses unique challenges. The three-phase windings of a generator are equal, but we have minimal control over the load. A more favorable scenario would be a small single-phase load complemented by a larger three-phase load — a situation that is uncommon.

ISSUES REQUIRING ATTENTION

Two significant problems need addressing:

- Avoiding generator damage from the unbalanced load.

- Preventing damage to three-phase motors connected to systems with unbalanced loads.

CONNECTING SINGLE-PHASE LOADS TO A THREE-PHASE DELTA SYSTEM

Shown in Figure 1 is a six-winding delta generator ultimately connected with three-phase terminals L1, L2, and L3, featuring a grounded neutral situated at L0. Unique to the 120/240-volt delta configuration is a phase with a higher voltage than the others. This higher phase, L2, boasts 208 V (phase to neutral/ground), known as high-leg or dogleg connection.

The unbalanced loads pose challenges, especially when applying to systems like the one converse at our company, Brags & Hayes Generators. However, with expert knowledge and a keen understanding of three-phase systems, we seek to address these problems and ensure the smooth operation of the systems we configure and supply.

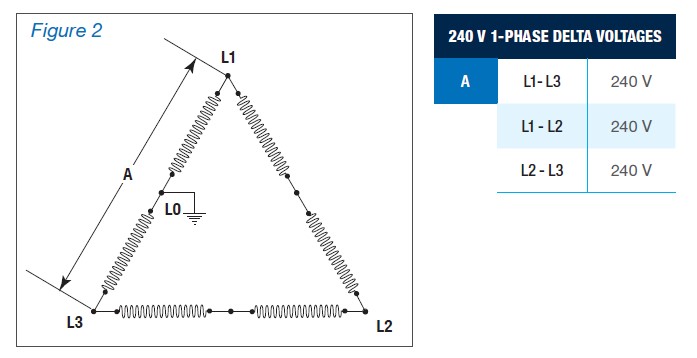

LOAD “A” 240-V SINGLE-PHASE CONNECTIONS

The challenge heightens when you examine LOAD “A” 240-V SINGLE-PHASE CONNECTIONS. As depicted in Figure 2, the higher single-phase 240-V connection in a three-phase delta system isn’t a simple plug-and-play connection type. Load A gathers its supply not only from windings between L1 and L0, L0 and L3 but also between L1 and L2, and L2 and L3. Here at Brags & Hayes Generators, we understand that currents tend to be higher in the L1 and L3 legs, but the system operates similarly to the more common double-delta system, frequently leveraged for single-phase generator connections.

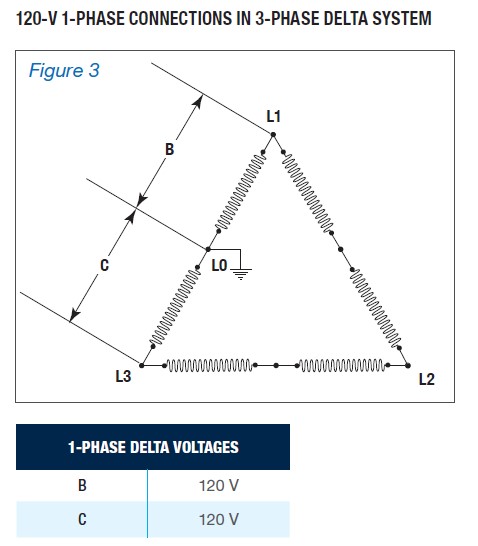

LOADS “B & C” 120-V SINGLE-PHASE CONNECTIONS

When it comes to LOADS “B & C” 120-V SINGLE-PHASE CONNECTIONS, complications can multiply if loads do not distribute evenly across B and C (Figure 3). For instance, if the load at B stands alone with nothing in C, a single coil of the generator’s six has to bear the entire load. This disparity can overload the generator coil.

Reducing the severity of this issue is possible by connecting a load balance at C. Equal loads at B and C act similarly to load A. Therefore, we always strive to maintain a close-to-equal amount of load at B and C locations as possible. Careful attention to these 120-V circuit load balances helps avoid generator damage.

However, despite these precautions, it is vital to keep in mind that the total single-phase plus three-phase current on terminals L1, L2, or L3 should not exceed the current rating of the generator voltage unbalance.

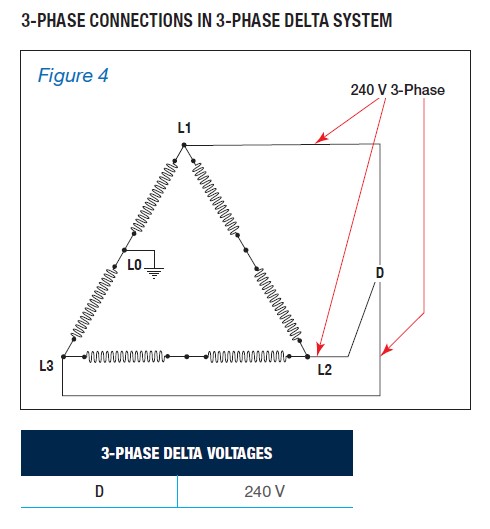

CONNECTING THREE-PHASE LOADS TO A THREE-PHASE DELTA SYSTEM

When connecting THREE-PHASE LOADS to a three-phase delta system (Figure 4), we enter another problem area, particularly when we consider three-phase loads such as at point D. A recommendation in NEMA MG1, section 12.45, suggests motor voltage unbalance should not exceed 1%. But, with single-phase loads equivalent to half the rating of the generator often found in these systems, the voltage unbalance in the three-phase lines can be several times 1%.

To avoid motor overheating, NEMA prescribes a system whereby motors are derated if unbalanced voltages exist. For example, at a 5% unbalance, the derate hits 25%, implying that the current unbalance at normal operating speed can be 6 to 10 times the voltage unbalance.

SUPPLYING AN OVERSIZED GENERATOR

SINGLE AND THREE-PHASE MOTOR LOADS

As we become more conscious of motor efficiencies, this situation may get to be more critical as designers will tend to operate motors near their full-load rating.

The only thing that the generator supplier can do to alleviate this problem is to supply an oversized generator. (Even RMS three-phase sensing on the voltage regulation does not help balance the voltages.)

If single-phase loads are very heavy and if the three-phase motors involved are loaded up to their rating, an oversized generator is recommended.

SIZING FUNDAMENTALS FOR THREE-PHASE DELTA SYSTEMS

Key basic points of sizing are:

- Balance the loads between L1–L0 and L3–L0.

- Try to keep the single-phase loads to less than 50% of the rating of the generator.

- Keep the line current at any of the three terminals, particularly terminals L1 and L3, within the current rating of the generator.

- Do not load connected motors beyond 80% of their full-load rating.

the complexities of unbalanced three-phase delta systems require a measured approach, deep knowledge, and particular attention to balancing loads and avoiding overloading.

Here at Brags & Hayes Generators, we work meticulously to fulfill these demands, ensuring that our supply systems operate seamlessly, efficiently, and effectively. If you have questions about generator installations, feel free to reach out to us. We’re available via the Whatsapp chat function on this page, email at info@bnhgenerators.com, and also by phone on +1.954.657.7777. We are always here to help!