In this article, we will succinctly explain the essence of the ISO 8528 standard and its significance for professionals in the energy generation sector. Additionally, we will provide insights on how this standard could play a pivotal role in the emergence of future energy-generating technologies.

ISO 8528 is a technical standard primarily laid down by the International Organization for Standardization (ISO) for describing the key concepts, requirements, and practices related to gensets, also known as generator sets. The full name of this technical monopoly is ISO 8528: Reciprocating Internal Combustion Engine Driven Alternating Current Generating Sets.

The ISO 8528 standard is a comprehensive suite consisting of 12 individual parts, each part addressing a specific aspect in terms of design, performance, operation, and test methods of generator sets. At its core, the ISO 8528 standard primarily deals with gensets used for supplying electrical power in case the usual power supply fails.

In other words, this norm augments reliability, ensuring that generator sets are of high quality, safe, efficient, and compatible. Moreover, it puts forth globally acceptable criteria that generator sets, being used in commercial, industrial, or domestic arenas, should meet to ensure they can provide the necessary assistance when primary power resources fail unexpectedly.

It is imperative to underline the fact that ISO 8528 covers both single unit gensets and those used as part of a larger system. It includes procedures to test the performance, monitor the operational behavior, measurement of mechanical vibration, and measurement of airborne noise.

In essence, ISO 8528 serves as a guidebook for manufacturers, developers, buyers, and owners in recognizing, understanding, and confirming the capabilities of generating sets. The application and persistence of these guidelines will undoubtedly lead to safer, more reliable, and high-performing gensets capable of handling today’s dynamic and demanding power needs. It is a fundamental standard to foster international commerce, promoting a level playing field for producers and protecting consumers.

Historical Context of ISO 8528

The origins of the ISO 8528 standard dates back to the late 20th century when the surging demand for reliable alternative power sources became apparent. Generator sets, which are standalone generators, were already one of the favored power alternatives, especially during power outages. However, the lack of uniform standards across countries led to quality and compatibility issues.

ISO, the International Organization for Standardization, as a global entity promoting proprietary, industrial, and commercial standards, identified this gap. Recognizing the importance of gensets in the global scene, ISO set out to establish clear, universal guidelines for the design, operation, and testing of gensets. This led to the creation of the ISO 8528 standard in 1986.

Historically, the ISO 8528 has undergone several revisions, enhancements, and expansions since its inception in 1986. Original standards largely focused on basic performance and safety metrics expected of gensets. However, the subsequent added parts took into account practicalities and industry advancements such as measurement of airborne noise by ISO 8528-10 in 1998 and the application of reference conditions and declarations of power, fuel, and lubricating oil consumptions, and test methods in ISO 8528-5 in the year 2005.

With the advent of an increasingly technologically advanced society with dynamic power needs, ISO 8528 continues to evolve, encompassing a wide array of circumstances, including sets working parallel with the grid, load acceptance criteria, or even remote monitoring protocols.

In a world where the demand for energy is ever-increasing and the assured supply is essential, the dynamic evolution of ISO 8528 ensures that generator sets are not just an emergency item, but a reliable, efficient, and high-performing power source that aligns with the global industrial standards.

Scope and Purpose of ISO 8528

ISO 8528 is a comprehensive compilation of standards that guide the design, performance, operation, and testing of reciprocating internal combustion engine-driven AC generating sets, commonly known as gensets or generator sets. The scope of ISO 8528 covers a broad range of gensets, including those intended for single unit operation and those intended for operation in parallel with other gensets, and with the power grid.

The primary purpose of having such a standard in place is to ensure consistency, reliability, and compatibility in genset usage worldwide. This means that gensets, irrespective of their origin or country of manufacture, must meet certain universally recognized and agreed-upon criteria in order to be declared fit for use.

From generator efficiency to mechanical vibration measurements to testing methodology and more, ISO 8528 clearly defines requirements, ensuring there are no ambiguities. This minimizes the risk of inaccurate genset ratings, unreliable performance, and potential safety hazards that could arise from products that do not fulfill the necessary quality criteria.

In terms of range, the ISO 8528 has several parts covering different aspects of generator sets:

- ISO 8528-1: General requirements.

- ISO 8528-2: Ratings and performance.

- ISO 8528-3: Alternating current generators for gensets.

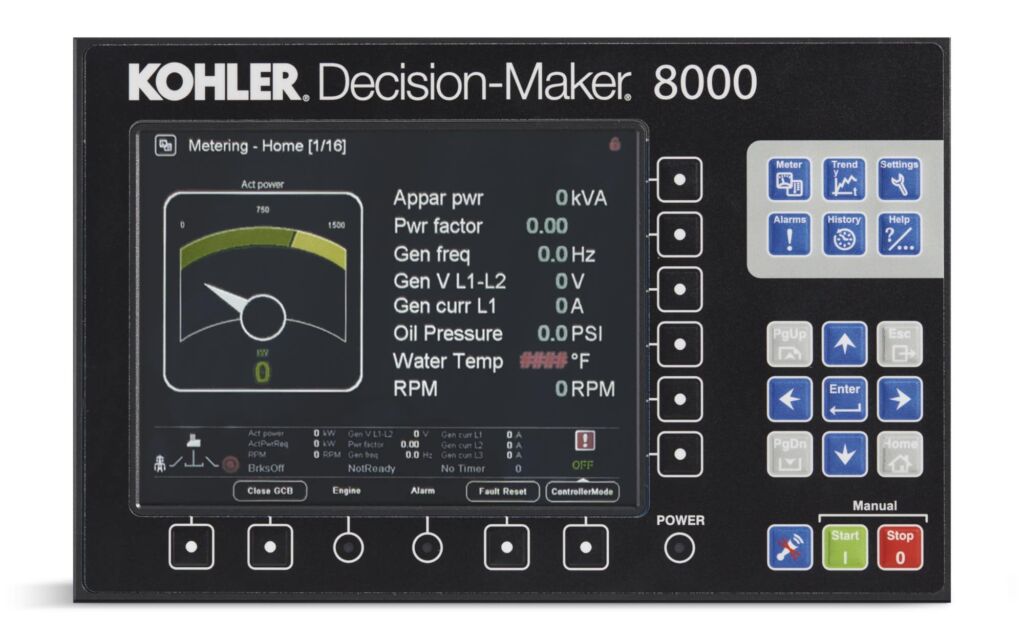

- ISO 8528-4: Controlgear and switchgear.

- ISO 8528-5: Generating sets.

- ISO 8528-9: Measurement and evaluation of mechanical vibrations.

- ISO 8528-10: Measurement of airborne noise.

- ISO 8528-12: Emergency power supply to safety services.

Ensuring consistency in genset performance, regardless of manufacturer or place of use, is critical. This guarantees reliability in emergency situations and prevents power disruptions from impacting essential services. By adhering to ISO 8528, manufacturers can ensure that their products are reliable, efficient, and safe, demonstrating compliance with globally recognized industry standards.

Classification of Power Generators in ISO 8528

The ISO 8528-1 is particularly relevant when discussing the classification of power generators. This part of the standard splits power generators into different categories based on their expected application and usage.

According to ISO 8528-1, power generators are classified into the following categories:

Continuous Power (COP): These generators are designed for an unlimited number of service hours. They are used for a constant load and typically operate at 100% load for an indefinite time.

Prime Power (PRP): These generators are used for unlimited hours and are often used as the main power source in areas where there is no connection to the grid. PRP generators can handle variable load. However, unlike continuous power generators, they have to operate with an average load factor of less than or equal to 70% of the PRP rating over 250 hours, within a period of one year.

Limited-Time Running Power (LTP): These generators are designed to load a maximum of 100% at variable electrical power. They are intended for usage during the period of intensive demand. The LTP rating should be applied for a maximum of 500 hours of operation per year.

Emergency Standby Power (ESP): These generators are reserved for cases of power outages in areas connected to the main grid. They are exclusively used during a power cut or failure. They can load a maximum of 70-80% and should be used for a maximum of 200 hours of operation per year.

Short-Time Operating Power (STOP): These generators are similar to ESP gensets, but the operating time is further limited to a total running time of 50 hours per year.

The ISO 8528 standard provides a clear framework for classifying different types of generator sets based on their power delivery and intended operating hours. This clarity is essential to ensure that a suitable generator set is selected, installed, and operated correctly depending upon its designated application. Each generator type is crucial to meet different demands in different situations.

Technical Requirements in ISO 8528

ISO 8528 series set out specific technical requirements for engine performance standards, fuel consumption metrics, and emission standards for generator sets.

Engine Performance Standards: ISO 8528-2 deals specifically with ratings and performance. This part outlines the standard reference conditions, declared powers, and the procedures for declaring net power output and energy conversion efficiency. It also provides detailed instructions on how to test generator sets for these criteria. It emphasizes the need for the equipment to meet certain standard rating conditions for obtaining accurate readings and comparisons.

Fuel Consumption: ISO 8528-5 focuses extensively on generator sets – including engine-driven alternating current (AC) generators. It lays down requirements for measuring and declaring the power, fuel and lubricating oil consumption, test methods, and operating requirements. It also stipulates the engine’s capability to handle different power loads efficiently, leading to optimized fuel consumption.

Emission Standards: Although ISO 8528 does not directly specify emission standards, it does emphasize efficiency, which inherently would result in reduced emissions. However, several regions around the world have their own regulations for allowable generator emissions, which manufacturers must comply with. For instance, in the USA, the Environmental Protection Agency (EPA) regulates genset emissions, and in Europe, the European Union has similar regulations.

It’s also important to note the ISO 8528-4, which deals with controlgear and switchgear, as it can also indirectly affect the final emissions by the effective control of the operational parameters of gensets.

In sum, the ISO 8528 series offers a detailed and comprehensive framework for generator set performance, fuel efficiency, and indirectly, emissions. Adherence to these standards ensures not only the reliability and performance of the equipment but also its ecological impact. As we see an increasing need for sustainable solutions in all sectors, strict adherence to these standards becomes even more critical.

Generator Set Parameters in ISO 8528

ISO 8528 provides a comprehensive scope dealing with multiple parameters of the generator sets (or gensets), including critical areas such as voltage and frequency tolerances as well as power factor considerations.

Generator Set Parameters: ISO 8528-1, the general requirements, provides an overview of genset parameters. It includes the type of application, duty, power factor, and characteristics of the load. These parameters are used to classify different gensets and make sure the right genset is used for the right application.

Voltage and Frequency Tolerances: These tolerances refer to the variations in voltage and frequency that a generator set can handle while still functioning within operational parameters. ISO 8528-8 introduces requirements and tests for voltage and frequency, ensuring that gensets can function correctly within predetermined parameters. This is critical, especially during load changes, to prevent any damage to connected equipment or devices.

Power Factor Considerations: The power factor is the ratio of the real power flowing to the load to the apparent power in the circuit. It is a measure of how effectively the generator set can convert electrical power into useful output power. It’s a crucial figure in genset design and operation. The standard power factor for generator sets as per ISO 8528 is 0.8 lagging, but it is understood that this can depend on the kind and characteristics of the load.

ISO 8528 soothes the process of delivering effective, reliable, and safe gensets. Understanding ratings and functionality, including generator set parameters, voltage and frequency tolerances, and power factor considerations, will unquestionably lead to more efficient and effective generator set performance. These metrics aid in making an informed choice, resulting in optimum operation and minimal damage risks.

Measuring and Testing Procedures in ISO 8528

ISO 8528 establishes a clear and universally agreed upon framework for measuring and testing generator sets. This involves standardized testing protocols, the acceptance criteria for different types of loads, and specific testing for transient response.

Measuring and Testing Procedures (Standardized Testing Protocols): ISO 8528 covers various aspects of testing gensets. For instance, ISO 8528-5 provides guidelines for testing and measuring genset power and fuel, and lubricating oil consumptions. These standardized protocols ensure that all gensets, regardless of the place of manufacture, are tested under the same conditions and that the results can be compared on an equal footing.

Load Acceptance Criteria: Load acceptance in ISO 8528 refers to the ability of the generator set to take on a specific load quickly. ISO 8528-2 addresses the concept of load acceptance. The standard classifies power into three levels: base load, prime power, and peak load. The transition from one load to another affects the performance of a genset; thus, genets are tested to see how well they can handle such transitions.

Transient Response Testing: Transient response testing checks how a genset reacts to the sudden changes in load. Transient reactions can cause a temporary drop in voltage and frequency, affecting the stable operation of the connected load. ISO 8528-9 touches on a similar concept when discussing evaluating mechanical vibrations — sudden load changes can also cause mechanical vibrations in the genset that must be measured and kept under minimal permissible levels.

By enforcing these measuring and testing procedures, ISO 8528 ensures that gensets perform optimally under changing conditions. This secures the stable operation of equipment reliant on gensets and ultimately minimizes the possibility of power disruptions.

ISO 8528 Compliance and Certification

Obtaining ISO 8528 certification requires in-depth understanding of the standard, comprehensive preparation, execution of proper testing protocols, and a commitment to continuous compliance.

Understanding the Standard: The first step is to purchase the relevant parts of the ISO 8528 standard series and conduct a thorough read-and-understand session. Depending on the type of generator set you manufacture, different parts of the standard series will apply to you.

Implement Design Controls: Build a quality management system that includes design controls in compliance with ISO 8528 requirements into your manufacturing process.

Perform Testing: Subject the gensets to the prescribed testing protocols as per the ISO 8528 series. This includes the measurement of genset power, fuel consumption, lubricating oil consumption, and mechanical vibrations, etc. Ensure that testing is conducted under standard reference conditions to maintain the validity and reliability of results.

Document Results: An essential part of certification requirements is collecting and maintaining records about your genset’s performance. Detailed documentation is critical as it serves as evidence of compliance during audits and reviews.

Third-Party Audit: ISO 8528 certification often involves a thorough third-party audit where the auditor verifies whether the manufacturer has established and maintained a quality management system in compliance with ISO standards. The auditor will evaluate all documented evidence, including test results and other production documents.

Continuous Compliance Maintenance: The certification is merely the first step, maintaining the achieved standards for ISO 8528 certification is an ongoing process. This requires periodic audits and recalibrations, continuous monitoring of processes, and taking corrective actions when necessary.

This is a simplified overview of the certification process and continuous compliance. The exact process may vary depending on the specifics of your genset models and regulatory requirements in your area. Always consult with ISO or an accredited and experienced ISO certification consultant to ensure a thorough understanding of compliance requirements.

ISO 8528 Harmonization with Other Standards

ISO 8528 standard, focusing on generator sets (gensets), collaborates with multiple other standards, including the globally renowned ISO 9001, quality management standard, as well as environmental standards.

Harmonization with ISO 9001: Both ISO 8528 and ISO 9001 emphasize a quality management system. While ISO 8528 handles the specifics related to gensets, ISO 9001 deals with the overarching quality management aspects that any organization, irrespective of its size or the industry it operates in, can adopt. There is a substantial synergy between these two standards, particularly in terms of documentation, maintaining quality procedures, continuous improvement, and customer satisfaction. By complying with ISO 9001, manufacturers can ensure the quality of their processes, resource management, and customer-oriented approach, complementing their efforts in meeting the ISO 8528’s technical requirements.

Aligning with Environmental Standards: ISO 8528 does not explicitly specify emission standards; however, it does emphasize efficiency, leading to reduced harm to the environment. Complying with ISO 14001, the standard for Environmental Management Systems, can be beneficial for genset manufacturers. ISO 14001 aims to help organizations manage their environmental responsibilities effectively. It encourages a systematic approach to setting environmental objectives and targets, achieving these, and demonstrating that they have been achieved. ISO 14001 pushes genset manufacturers forward in a direction to not only consider metrics like efficiency but also the environmental impact of their products.

Apart from ISO 9001 and 14001, harmonization with other standards such as ISO/IEC 17025 for Testing and Calibration Laboratories, ISO 45001 for Occupational Health and Safety, among others, can amplify the effectiveness of adhering to ISO 8528.

ISO, as an organization, emphasizes the harmonization of standards, promoting an integrated approach. This approach paves the way for a holistic view, ensuring quality, safety, and a green approach in the genset industry. Manufacturers that take the initiative to comply with these interconnected standards could stand out in the international marketplace as they are not only technically competent but also environmentally conscientious and quality driven.

Future Trends

ISO 8528, like all other ISO standards, is designed to evolve and adapt to emerging trends and technologies. This ensures its continued relevance and applicability in a rapidly changing industry landscape. These adaptations include but are not limited to:

Digitalization and Automation: As digitalization and automation have surged in nearly all sectors, genset manufacturing and operation have been no exception. The up-to-date sections of the ISO 8528 standard address these advancements, covering areas like digital controls and automated genset management. For instance, ISO 8528-12 focuses on the application of gensets for safety services, emphasizing control systems that automatically adjust to ensure continuous services.

Green Energy and Sustainability: The usage of more environmentally-friendly fuels and the incorporation of renewable energy sources into genset operation are growing trends in the industry. While the ISO 8528 standard does not explicitly deal with these features, it does emphasize efficiency – promoting the efficient use of fuel and less wastage inherently aligns with the principles of green energy and sustainability.

Remote Management and Internet of Things (IoT): Developments in remote monitoring and management have made managing gensets more efficient and easier than in the past. The advent of IoT is increasingly being integrated into genset management protocols, which the ISO 8528 standards recognize and accommodate.

Noise and Vibration Control: Advances in noise and vibration mitigation in gensets have become more critical due to increasing concerns about the health and safety of operations teams and the surrounding environment. Parts of ISO 8528 like ISO 8528-9 and ISO 8528-10 cover measurement and evaluation of mechanical vibrations and measurement of airborne noise.

It’s crucial to note that the ISO periodically reviews and revises its standards to ensure they stay relevant and beneficial. As such, future versions of ISO 8528 will likely include more explicit provisions for the above trends and any new developments in this sector.

Economic Impacts

Implementing and complying with ISO 8528 for generator sets, although involving some costs upfront, presents significant benefits from both an economic and operational perspective. Here’s a brief breakdown of some of these aspects:

Costs Involved: The initial expenses incurred in complying with ISO 8528 include purchasing the standard, testing equipment, and potential re-designing and re-manufacturing to meet the stipulated standards. If a third-party audit is needed for ISO certification, this will incur additional cost. There may also be ongoing costs associated with implementing and maintaining an ISO quality management system and ensuring continuous compliance with the standard.

Benefits of Adherence: Cost-effectiveness and operational efficiency are the major benefits of ISO 8528 compliance. Well-designed and well-manufactured gensets maximize output while minimizing fuel consumption, thus leading to cost savings over the genset lifecycle. Conforming to ISO 8528 means the gensets are of high quality, reliable, and safe, which reduces the likelihood of operational failures and the associated repair and downtime costs.

Market Advantage: Moreover, having ISO 8528 compliant gensets can offer a competitive edge in the marketplace. It opens up opportunities in international markets where regulatory bodies mandate ISO certification.

Economic Efficiency: Generators that adhere to ISO 8528 are more likely to have optimized fuel consumption, owing to stringent testing in line with ISO 8528-5, hence providing economic efficiency. Also, a high-quality generator that is more reliable reduces the frequency of breakdowns, thereby decreasing maintenance expenses and potential loss from operational downtime.

While there are apparent costs associated with adherence to ISO 8528, the long-term benefits in terms of operational efficiency, reliability, market competitiveness, and customer confidence make it a worthwhile investment. Overall, ISO 8528 adherence serves to optimize the performance of gensets, leading to lower operational costs and improved economic efficiency in power generation.

ISO 8528's Regulatory Influence

As an international standard by the International Organization for Standardization (ISO), ISO 8528 has a significant role in shaping national regulations and influencing regulatory bodies worldwide. Here’s an insight into its global impact:

Influencing National Regulations: ISO 8528 acts as a benchmark for many countries when forming their regulations related to generator sets or gensets. National authorities often either directly adopt or use ISO standards as a guide to develop their regulations to ensure the safety, compatibility, and efficiency of gensets used within their jurisdictions. Adopting such globally recognized standards allows seamless international trade and ensures the safety and performance level of gensets imported from other countries.

Collaboration with Regulatory Bodies: National standardization bodies that are members of ISO participate actively in the process of formulating and revising standards like the ISO 8528. This ensures that the specific needs and existing regulations of member countries are incorporated. Moreover, ISO collaborates with regulatory bodies to provide accurate and up-to-date guidance for industries, and regulatory bodies, in turn, can use ISO 8528 as a reference in the formation of their laws and regulations.

Enabling International Trade: Governments and regulatory bodies worldwide recognize ISO 8528, making it easier for businesses to export and import gensets and services associated with them, reducing technical barriers to global trade.

Standardization and Enhancing Public Safety: By providing guidelines that help genset manufacturers develop safe and efficient products, ISO 8528 plays a vital role in enhancing public safety. Regulatory bodies often collaborate with ISO or use ISO standards like ISO 8528 as a baseline to develop their protocols to ensure safety and quality control in genset production and performance.

ISO 8528 has a significant influence on the development of national regulations and policies connected to gensets around the globe. It fosters international collaboration, enabling the sharing of best practices and facilitating global trade.

The ISO 8528 standard stands at the forefront of the power generation industry, providing a robust framework for ensuring the reliability and performance of generator sets. Originating from a rich historical context, this standard has evolved to become a pivotal force in the global energy landscape.

ISO 8528’s impact on the power generation industry is multifaceted. From its historical roots to its future adaptation, the standard serves as a guiding force for reliability, performance, and sustainability.

As the power generation landscape evolves, ISO 8528 stands poised to play a crucial role in shaping the future, ensuring that generators continue to meet the highest standards of performance and environmental responsibility.