This article summarizes the white paper “Designing Enclosures for Hurricane Ratings and the Florida Building Code” by Jacob Vanderloop is a Senior Design Project Engineer with Kohler Co.

While thunder rumbles and lightning flashes, standby power systems serve as the last line of defense during extreme weather events like hurricanes, by providing crucial power support to essential facilities like hospitals, emergency centers, and shelters. Ever stood in Florida during a hurricane? Some of the most hostile weather conditions in the United States unfurl here.

According to the National Oceanic and Atmospheric Administration (NOAA), the wind speeds during these storms can exceed 180 mph. Considering these extreme conditions, Florida has established a thorough system of testing protocols and regulations for structures that include crucial power systems. The Florida Building Code (FBC) contains these guidelines and evaluates the ability of enclosures to withstand wind load, shield against rain, and repel wind-borne debris impact.

It is critical to incorporate these factors when mapping out a power system enclosure. The aim is to ensure that power systems remain operational when needed the most. This article will walk you through these critical design elements and ensure your understanding of the requirements for conformity to hurricane ratings and the FBC.

The Florida Building Code (FBC) serves as a guideline for construction and building undertakings in the state, taking root in 2002. Instated by the Florida administration, this unified state building code is enforced by all local governing bodies. Its core intention is to safeguard the building structures within Florida, ensuring that they possess the strength to withstand hurricanes and other catastrophic natural events.

The FBC follows a classification approach to buildings, basing it on their occupancy risk as stated in section 1604.5. Four categories exist that evaluate the structures’ purpose and potential associated risks. This classification aids in aligning the construction of the buildings and structures with their original utility and specifications. The FBC allocates a risk category to every building and structure.

These risk categories exhibit minor variations contingent upon the building’s intended utilization. A case in point is essential facilities such as hospitals and nursing homes, which fall under risk category IV. These risk categories permeate into every corner of Florida, incontrovertible of geographical location. Furthermore, FBC’s Chapter 4 elaborates on distinct requirements and guidelines for a variety of structures relative to their occupancy and utility. To determine the specific requirement for any structure within Florida, this chapter is an indispensable reference.

For reference from the FBC you can download the following document:

NAVIGATING THROUGH HIGH-VELOCITY HURRICANE ZONES

FBC contains specific regulations concerning standby power system enclosures. These rules ensure that the enclosures are secure, particularly in High-Velocity Hurricane Zones (HVHZ), which include counties like Miami-Dade and Broward. These zones experience some of the most severe weather conditions during a hurricane. HVHZ stipulate the maximum requirements for critical power systems as per FBC.

For validation of structural integrity, standby power system enclosures are subjected to rigorous assessments that define their resilience against wind load, rain intrusion, and impacts from wind-borne debris. Compliance with these safeguards ensure reliable operation of the power system during adverse weather conditions.

EVALUATING RISK CATEGORIES

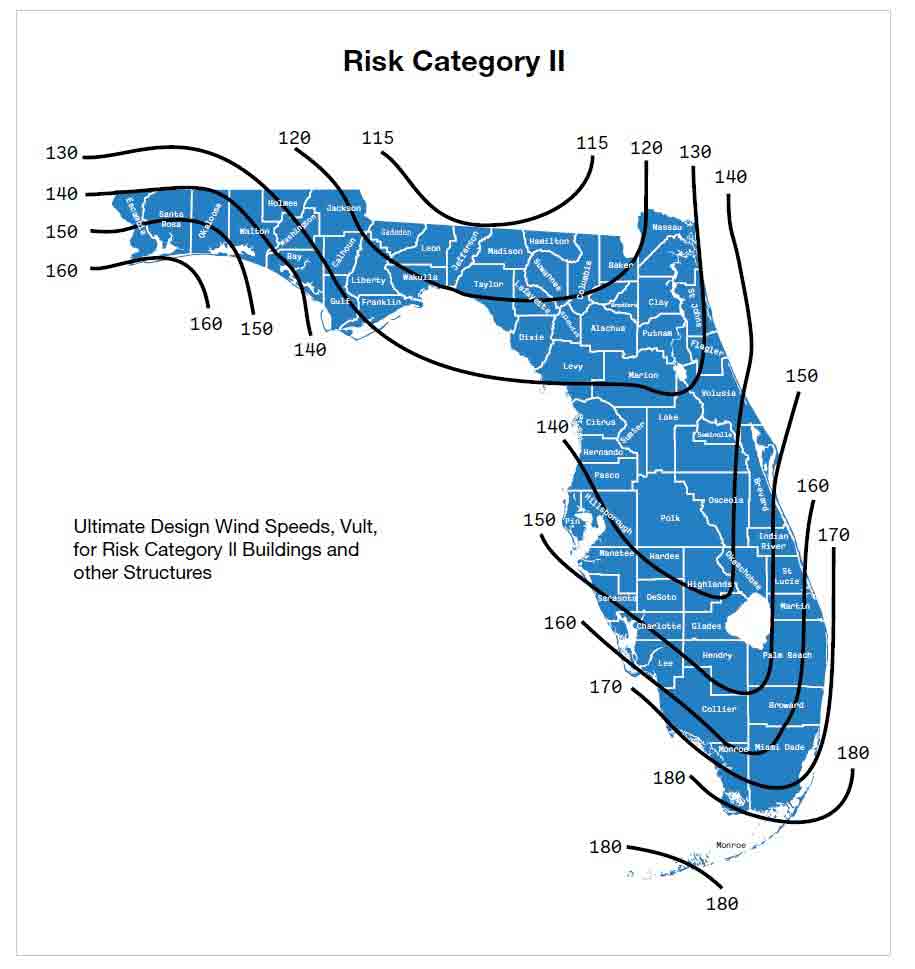

Section 1620 of FBC elucidates the wind load requisites for structures in HVHZ. This section requires every building to be designed in accordance to the ASCE 7-10, and chooses the risk category based on its usage. Standby power systems generally fall under Risk Categories II, III, and IV. The following image depicts the basic wind speeds for Risk Category II in Florida.

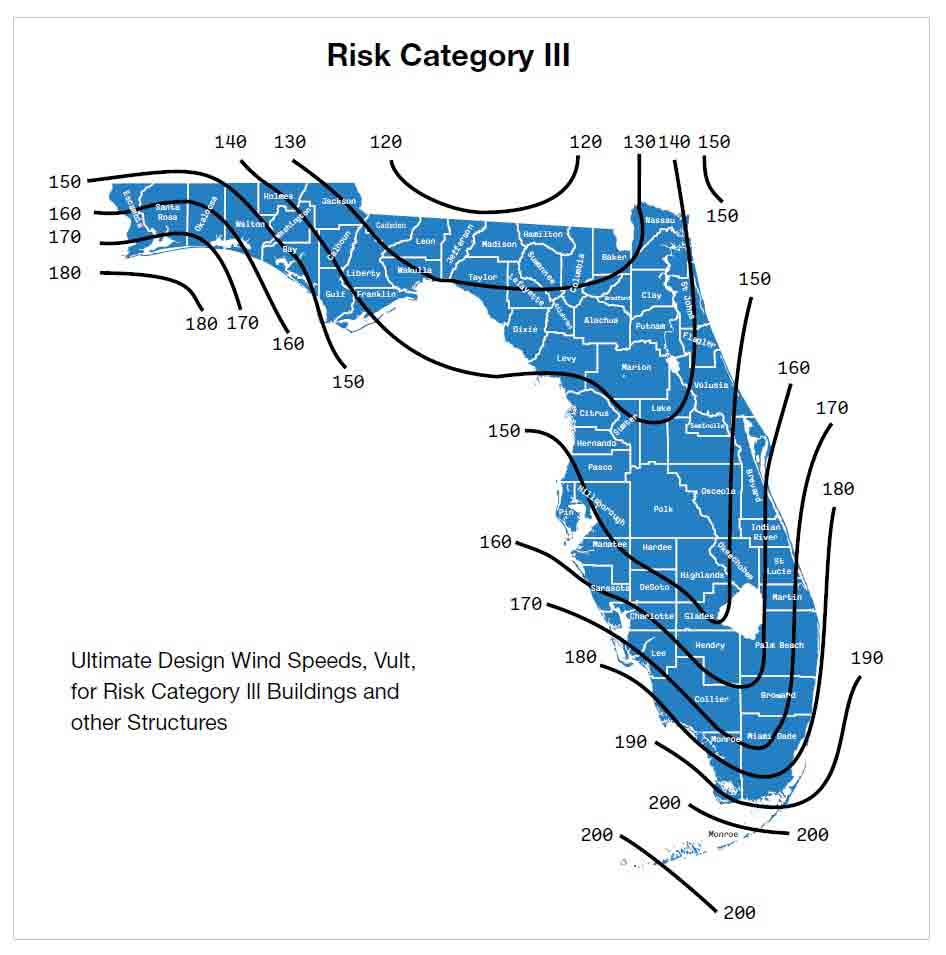

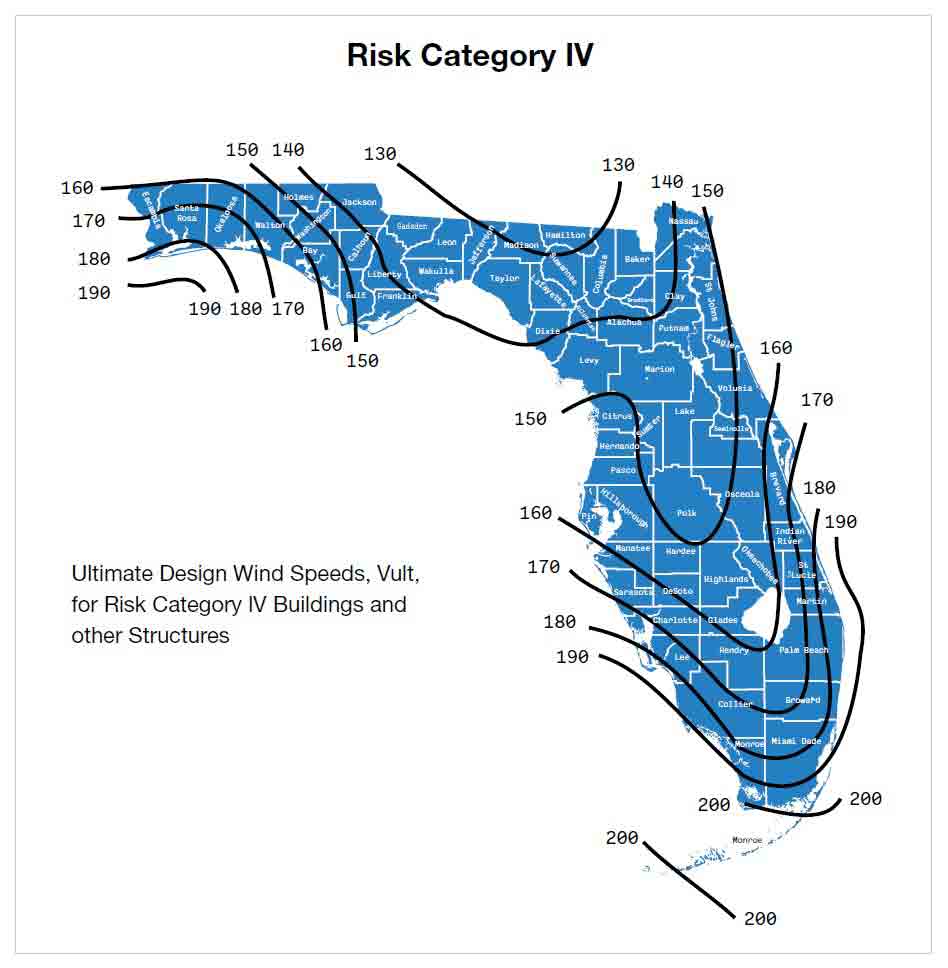

The following images illustrate the basic wind speeds in the state of Florida for Risk Categories III and IV, respectively.

USING DESIGN METHODS

Wind load simulations are an acceptable method to determine the resilience of any structure against wind loads. Section 1620.2 of FBC circumscribes wind speeds for structures within HVHZ based on their risk category. Once a risk category is established, these wind speeds can be employed in determining strategies and calculations for designing power systems enclosure.

Section 1620.2 of the Florida Building Code

1620.2 Wind velocity (3-second gust) used in structural calculations shall be as follows:

– Miami-Dade County

- Risk Category l Buildings and Structures: 165 mph

- Risk Category ll Buildings and Structures: 175 mph

- Risk Category lll Buildings and Structures: 186 mph

- Risk Category lV Buildings and Structures: 195 mph

– Broward County

- Risk Category l Buildings and Structures: 156 mph

- Risk Category ll Buildings and Structures: 170 mph

- Risk Category lll Buildings and Structures: 180 mph

- Risk Category lV Buildings and Structures: 185 mph

MANAGING RAINWATER INTRUSIONS

Water is a significant threat to standby power systems. While maintaining the airflow for efficient system operation is necessary, it is also vital to protect the system from rainwater entering the ventilation sources.

UL 2200 prescribes standards for protecting power systems from water and optimizes its functionality. Testing protocols under this standard corroborate the ability of the enclosure to withstand rainwater intrusion.

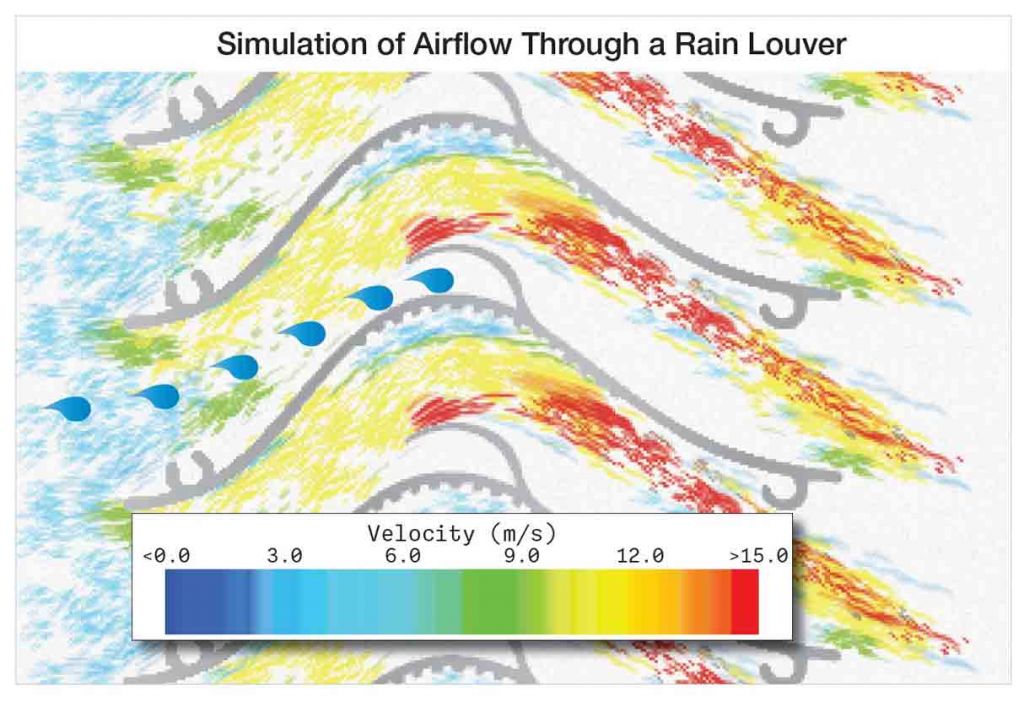

CREATING EFFECTIVE LOUVER DESIGNS Kohler, for instance, uses a vertical high-velocity rain louver design to comply with UL 2200 standards. They employ testing methods such as Computational Fluid Dynamics (CFD) to validate the enclosure’s effectiveness against high-velocity rain and to maintain adequate airflow within the power system.

The following image demonstrates the airflow through a high-velocity rain louver using CFD simulation. As shown in the image, air enters the louver at a maximum velocity of 6.5 m/s (1,250 ft/min). Air can be seen simultaneously accelerating and turning once entering the louver. The air can make the curve of the louver while the water particles cannot. These water particles are then trapped by the C-shape profile.

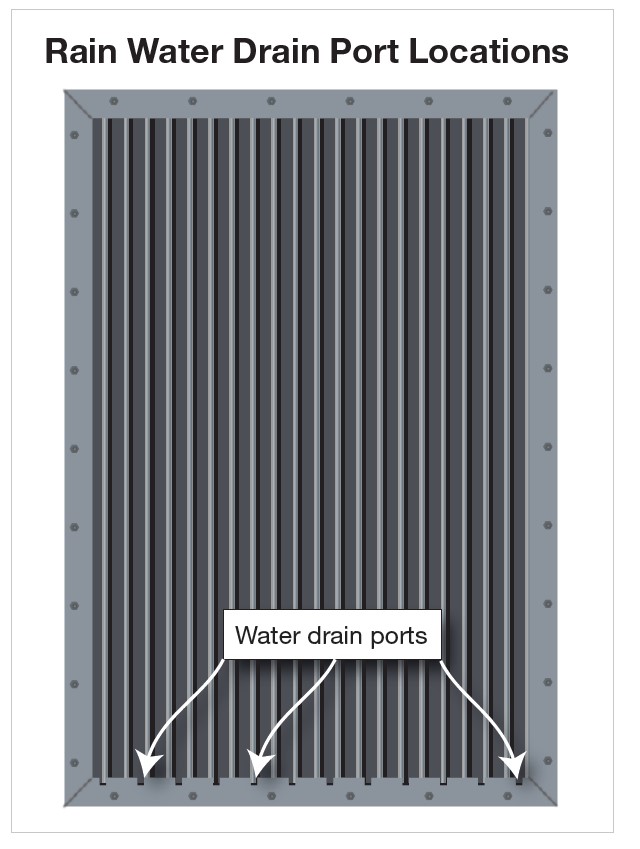

Gravity assists in draining water out the bottom of the louver through the drain ports shown in Figure 6. The airflow then can be seen accelerating and continuing through the louvers and into the power system enclosure.

It is important to note that air restriction is an important factor when sizing a rain louver and to verify that the power system receives an adequate amount of airflow to remain functional.

IMPACT TESTING AGAINST WIND-BORNE DEBRIS

In hurricane-prone regions like Florida, wind-borne debris could pose an enormous threat. So, assessing the ability of the enclosure to stand strong against such debris during torrential wind conditions is essential.

FBC in its section 1626 prescribes the required impact protection standards. The structures are subjected to rigorous missile impact testing, conducted as per TAS 201 and TAS 203 protocols. These tests prioritize the structural integrity and safety of the enclosures.

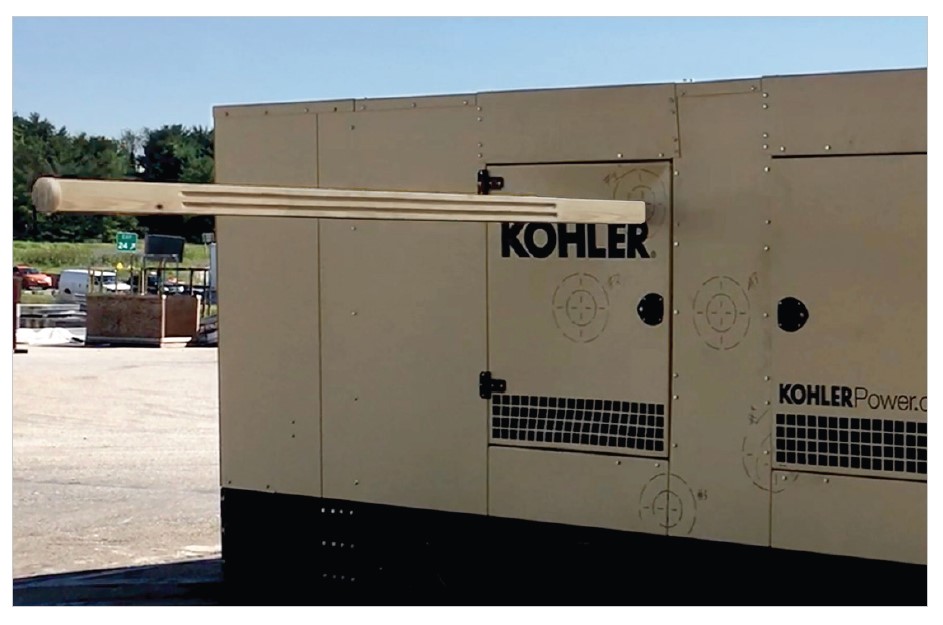

DETAILED TESTING METHODS Missile impact tests involve launching simulated missiles, such as wooden two-by-fours, at a breakneck pace towards the enclosure. This procedure assesses the resistance of enclosures to penetration and structural damage from wind-borne debris.

The following testing requirements are outlined in section 1626.2 through 1626.4 of FBC.

- This testing shall be conducted on at least three fully assembled enclosure units.

- The large missile shall be comprised of a piece of timber having nominal dimensions of two inches by four inches weighing nine pounds (4.1 kg).

- The large missile shall impact the surface of each test specimen at a speed of 50 feet per second (15.2 m/s) and 80 feet per second (24.38 m/s) for Risk Category IV (essential facility building or structures).

- Each test specimen shall receive two impacts at each specified location.

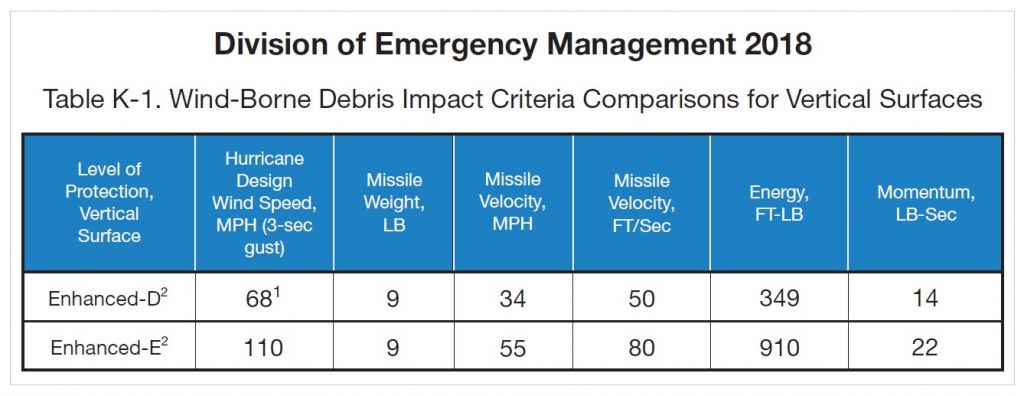

It is important to note that Risk Category IV structures, such as essential facilities buildings or structures, require missile impact testing to be completed at 80 feet per second (24.38 m/s) per 1626.2.4 of FBC. Table below from the Division of Emergency Management 2018, compares the level of protection D and E based on the difference in missile velocity 50 ft/sec (15.2 m/s) vs. 80 ft/sec (24.38 m/s) respectively.

EVALUATION CRITERIA

Successful completion of missile impact testing deems standby power system enclosures eligible for certification indicating FBC compliance. This certification aids building inspectors in verifying adherence to regulations during the permitting inspection process. To gain FBC certification, the enclosure needs to satisfy the subsequent pass/fail criteria:

- No disengagement of any panel or fastener (FBC 5.1.3).

- No opening exceeding 3.0″ in diameter.

- Absence of projectile penetration into the enclosure.

- Functional access doors (capable of opening and closing) post-impact.

APPLYING SIMULATION TECHNIQUES

Tools like computational simulation and analysis, particularly finite element analysis (FEA), play a crucial role in shaping the design process of a power system enclosure. Impact simulations aid in identifying potential weak points and areas before the actual missile impact testing.

Simulation capabilities provide a chance to modify the design of the enclosure before the building and testing stage. A depiction of impact testing simulations can be seen in the following image. This illustration underscores the precision of FEA simulations and reveals potential failure points in the enclosure design.

The following image offers a comparison between impact testing simulations and the phenomena observed during actual missile impact testing. In the simulation, it’s seen that the access door becomes concave upon being hit by the simulated missile. Similar effects can be witnessed during the actual missile impact testing (following image), but now with the designed bracing included to withstand the test.

Besides understanding the testing methods, effective rain resistance, louver designs, and evaluating risk categories, it is critical to consult the FBC and local jurisdiction to ensure effective design and regulatory compliance of the product. As Florida continues to battle against hurricanes, those who make their homes there can rest assured that the power will stay on, even in the stormiest weather.

If you have questions about hurricane ratings or purchasing a certified generator and enclosure package, feel free to reach out to us. We’re available via the Whatsapp chat function on this page, email at info@bnhgenerators.com, and also by phone on +1.954.657.7777. We are always here to help!