The global energy landscape is at a crossroads. The twin challenges of ensuring reliable power generation and addressing the climate crisis demand innovative solutions. For engineers, especially those involved in the design and implementation of backup power systems, the need for technical expertise in sustainable practices has never been greater. This post delves into the future of clean and ecological energy production, offering insights into the technical advancements that can help achieve this goal.

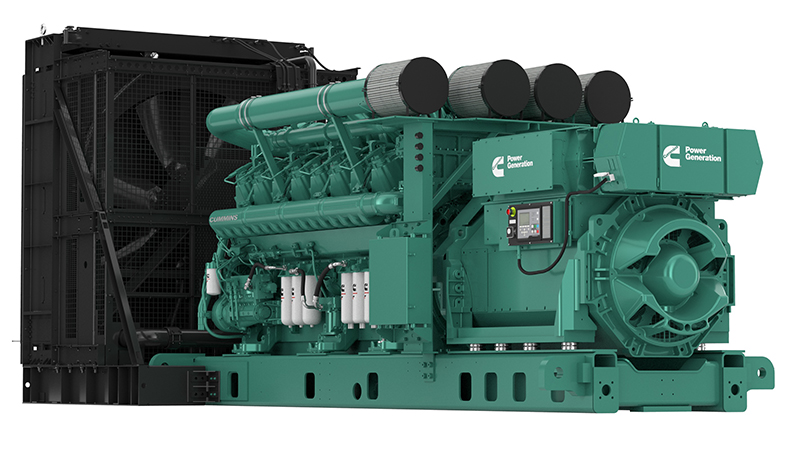

Modern power generation faces two major imperatives: reliability and sustainability. Backup power systems, such as diesel generators, remain indispensable for critical applications like hospitals, data centers, and water treatment facilities. However, traditional energy sources contribute significantly to global carbon emissions, which exacerbate climate change and threaten the environment.

The growing urgency to reduce greenhouse gas (GHG) emissions has led to stringent regulatory measures worldwide, such as the EPA standards in the U.S. and Stage V engine standards in Europe. These regulations challenge engineers to rethink the role of fossil fuel-based generators while exploring clean alternatives like hydrogen fuel cells and utility-scale batteries.

Evolutionary and Revolutionary Approaches to Cleaner Power

Diesel Engine Advancements

Diesel generators are often criticized for their environmental impact, but ongoing innovations have made them cleaner than ever. By optimizing internal combustion engine designs and employing advanced exhaust treatment technologies—such as diesel oxidation catalysts (DOCs), diesel particulate filters (DPFs), and selective catalytic reduction (SCR)—engineers have significantly reduced particulate matter (PM) and nitrogen oxide (NOx) emissions.

Moreover, the use of biofuels, particularly hydrotreated vegetable oil (HVO), has emerged as a viable solution. These synthetic fuels, derived from renewable feedstocks, offer a seamless transition for existing diesel systems while reducing lifecycle carbon emissions by up to 80%. HVO fuels also demonstrate superior storage stability and compatibility with conventional engines, making them an attractive option for mission-critical applications.

Diesel engines have long been the backbone of mission-critical power systems, offering unmatched reliability, scalability, and performance under extreme conditions.

Advanced Engine Design and Combustion Optimization

One of the most significant areas of progress in diesel engines lies in the optimization of combustion processes. Engineers have focused on enhancing fuel atomization, mixing, and combustion chamber geometry to improve efficiency and reduce harmful emissions. Key innovations include:

High-Pressure Common Rail Systems:

These systems deliver fuel to the combustion chamber at pressures exceeding 2,000 bar, allowing for finer atomization and more uniform fuel-air mixing. The result is a cleaner, more complete burn, which minimizes unburned hydrocarbons (HC) and particulate matter.Variable Geometry Turbochargers (VGT):

By adjusting the turbocharger’s turbine geometry in real-time, VGTs maintain optimal airflow across varying engine loads. This not only improves power delivery but also reduces NOx emissions by maintaining ideal combustion temperatures.Low-Temperature Combustion (LTC):

Advances in LTC techniques, such as Homogeneous Charge Compression Ignition (HCCI), have shown promise in reducing NOx and soot formation. By controlling the timing and temperature of combustion, LTC achieves near-complete fuel oxidation, reducing pollutants at their source.Improved Lubrication Systems:

High-performance lubricants, designed to reduce internal friction and resist thermal degradation, contribute to lower emissions and improved engine longevity. These oils are formulated to work harmoniously with advanced exhaust after-treatment systems.

Exhaust After-Treatment Technologies

Modern diesel engines now rely heavily on sophisticated exhaust after-treatment systems to achieve compliance with stringent emissions regulations, such as the EPA Tier 4 standards in the U.S. and the EU Stage V standards. These systems work to neutralize or capture harmful pollutants before they are released into the atmosphere.

Diesel Oxidation Catalysts (DOCs):

DOCs are designed to convert carbon monoxide (CO) and unburned hydrocarbons (HC) into less harmful carbon dioxide (CO2) and water vapor through catalytic oxidation. These systems are effective in reducing visible smoke and odor from diesel exhaust.Diesel Particulate Filters (DPFs):

DPFs trap and remove up to 95% of particulate matter from the exhaust stream. Advanced designs include active regeneration systems, which use sensors and controlled heating to burn off accumulated soot, ensuring consistent filter performance.Selective Catalytic Reduction (SCR):

SCR systems use a urea-based solution, commonly known as Diesel Exhaust Fluid (DEF), to chemically reduce NOx emissions. When injected into the exhaust stream, DEF reacts with NOx to form harmless nitrogen (N2) and water (H2O). This technology has been pivotal in meeting the strictest emissions standards without sacrificing engine efficiency.Exhaust Gas Recirculation (EGR):

EGR systems recirculate a portion of exhaust gases back into the engine’s air intake, lowering the combustion temperature and reducing NOx formation. Recent developments have improved EGR flow control, resulting in greater system reliability and reduced maintenance requirements.

The Role of Alternative Fuels: A Bridge to Sustainability

While technological advancements in diesel engines have significantly reduced emissions, the choice of fuel remains a critical factor. Engineers are now focusing on integrating alternative fuels that align with existing infrastructure while offering substantial environmental benefits.

Hydrotreated Vegetable Oil (HVO):

HVO is a next-generation biofuel derived from renewable feedstocks such as vegetable oils, animal fats, and agricultural residues. Its chemical properties closely mimic those of conventional diesel, enabling seamless compatibility with existing engines. HVO also boasts excellent storage stability, high cetane numbers for improved combustion, and a potential lifecycle reduction in carbon emissions of up to 80%.Fatty Acid Methyl Ester (FAME):

Produced through the transesterification of oils or fats, FAME is a biodiesel that can be blended with traditional diesel. Although it offers environmental benefits, such as lower CO2 emissions, its higher susceptibility to oxidative degradation and microbial growth in storage requires careful handling and system modifications.Pathway Technologies for Cleaner Diesel:

Emerging research focuses on blending synthetic fuels or green diesel with conventional diesel to create cleaner-burning mixtures. These fuels are engineered to reduce soot and NOx formation while maintaining energy density and engine compatibility.

Overcoming Operational Challenges

Despite these advancements, engineers must address several operational challenges to maximize the benefits of modern diesel technologies:

- Fuel Quality Control: Contaminated or low-grade fuel can compromise engine performance and damage after-treatment systems. Advanced filtration and monitoring systems are critical to maintaining fuel integrity.

- System Integration: The addition of after-treatment systems increases engine complexity, requiring precise integration and calibration to ensure optimal performance.

- Cost vs. Benefit Analysis: While advanced diesel systems reduce emissions, their initial cost is higher. Engineers must evaluate the total cost of ownership (TCO), balancing upfront investments against long-term savings in fuel efficiency and regulatory compliance.

Diesel’s Role in the Energy Transition

Although renewable technologies like hydrogen fuel cells and battery storage systems are gaining traction, diesel remains irreplaceable for many mission-critical applications, particularly in regions with limited access to renewable energy infrastructure. Advances in diesel technology are not just a stopgap but a crucial element in the global energy transition.

Engineers must continue to push the boundaries of what diesel engines can achieve, leveraging incremental innovations in engine design, fuel systems, and alternative fuels. By doing so, the industry can ensure that diesel generators remain a sustainable and reliable component of the energy mix, supporting the world’s critical infrastructure while reducing environmental impact.

By prioritizing research, innovation, and collaboration, diesel engine technology can continue to evolve, proving that sustainability and performance are not mutually exclusive. As engineers work toward cleaner energy solutions, the advancements in diesel technology demonstrate a commitment to balancing today’s energy demands with tomorrow’s environmental imperatives.

Utility-Scale Batteries: A Complementary Solution

Utility-scale batteries have emerged as a pivotal technology in the quest for cleaner energy systems, offering unique opportunities to reduce reliance on fossil fuels while enhancing grid stability. These systems, driven by advances in lithium-ion and other emerging battery technologies, have proven their value as a complement to traditional power sources like diesel generators. For engineers, understanding the intricacies, benefits, and limitations of utility-scale batteries is critical to designing hybrid systems that meet both environmental and operational demands.

How Utility-Scale Batteries Work

Utility-scale batteries function as large energy storage units that can store electricity generated during periods of low demand or high renewable energy production. The stored energy is then discharged to the grid or an isolated system when demand peaks or when renewable sources like wind and solar are unavailable. This capability makes batteries ideal for applications requiring rapid response times and flexible energy supply.

The backbone of utility-scale battery systems is lithium-ion technology, known for its high energy density, efficiency, and scalability. These batteries consist of interconnected cells that store and release energy through electrochemical reactions, controlled by advanced battery management systems (BMS). The BMS ensures the system operates within safe parameters while optimizing performance and lifespan.

Integration with Renewable Energy

One of the most promising applications of utility-scale batteries is their integration with renewable energy sources. Renewable energy generation, such as solar and wind, is inherently intermittent. Batteries bridge this gap by storing excess energy generated during sunny or windy conditions and releasing it during cloudy or calm periods.

Key benefits of this integration include:

- Grid Stability: Batteries help balance supply and demand on the grid, smoothing out fluctuations caused by variable renewable generation.

- Load Shifting: By storing energy during off-peak hours and discharging it during peak demand, batteries can reduce strain on the grid and lower energy costs.

- Microgrid Support: In isolated or remote areas, utility-scale batteries combined with renewables can create self-sufficient microgrids, reducing dependence on diesel generators.

Advantages of Utility-Scale Batteries in Backup Power

While traditional diesel generators remain the go-to solution for mission-critical backup power, utility-scale batteries offer complementary benefits that enhance overall system performance:

- Instantaneous Response: Unlike generators, which require a short startup time, batteries can deliver power almost instantaneously, ensuring seamless transitions during outages.

- Reduced Emissions: By offsetting the need for diesel generators to run continuously during peak loads, batteries contribute to significant reductions in greenhouse gas emissions.

- Energy Efficiency: Batteries minimize energy losses associated with frequent generator cycling, improving the efficiency and longevity of hybrid systems.

For example, data centers—a major user of backup power systems—are exploring battery solutions to reduce their environmental footprint while maintaining reliability. Lithium-ion battery banks can handle short-duration outages or work alongside diesel generators, reducing the frequency of generator use and their associated emissions.

Challenges and Limitations

Despite their advantages, utility-scale batteries face several challenges that engineers must address when considering their deployment:

Energy Density and Scalability:

While lithium-ion batteries have high energy density compared to older technologies like lead-acid, they still require significant space for large-scale applications. For urban environments, such as data centers in metropolitan areas, space constraints can limit battery system deployment.Duration of Energy Supply:

Current battery technologies are best suited for short-duration energy needs, typically lasting a few hours. For prolonged outages lasting days, diesel generators remain indispensable. Engineers must design hybrid systems that leverage the strengths of both technologies.Thermal Management:

Utility-scale batteries generate heat during charging and discharging, necessitating robust thermal management systems. Without proper cooling, battery efficiency and lifespan can be compromised.Cost and Resource Availability:

Lithium-ion battery systems are capital-intensive, and their widespread adoption has raised concerns about the availability of key raw materials like lithium, cobalt, and nickel. This challenge has spurred interest in alternative chemistries, such as lithium iron phosphate (LFP) and solid-state batteries, which promise greater resource sustainability and lower costs.Degradation and Recycling:

Over time, battery cells degrade, leading to reduced capacity and efficiency. Engineers must factor in the lifecycle of batteries, including recycling and disposal, to ensure long-term sustainability. Emerging technologies, such as second-life battery programs and advanced recycling techniques, are addressing these concerns.

Emerging Technologies in Utility-Scale Batteries

To overcome current limitations, researchers and engineers are exploring new battery technologies that could redefine the role of energy storage in clean power systems:

Solid-State Batteries:

Solid-state batteries replace the liquid electrolyte in traditional lithium-ion cells with a solid material, improving energy density, safety, and lifespan. These batteries are expected to revolutionize utility-scale storage, though their commercialization is still in its early stages.Flow Batteries:

Flow batteries use liquid electrolytes stored in external tanks, allowing energy capacity to be scaled independently of power output. These systems are well-suited for grid-scale applications requiring long-duration energy storage.Hybrid Energy Storage Systems (HESS):

HESS combines multiple storage technologies, such as lithium-ion and flywheels, to optimize performance across various load conditions. These systems offer enhanced flexibility, efficiency, and reliability.Thermal Energy Storage:

Thermal systems store energy in the form of heat, which can be converted back to electricity when needed. While less common than electrochemical storage, these systems have potential for grid integration and industrial applications.

The Role of Utility-Scale Batteries in Hybrid Systems

Rather than replacing diesel generators outright, utility-scale batteries are best deployed as part of hybrid systems that capitalize on the strengths of both technologies. For instance, during a power outage, batteries can provide immediate power, allowing diesel generators to start up smoothly and operate at optimal load conditions.

In a hybrid system, utility-scale batteries also enable:

- Peak Shaving: Reducing peak demand on generators by handling short bursts of high power requirements.

- Load Leveling: Smoothing out fluctuations in power consumption, improving generator efficiency.

- Energy Arbitrage: Storing energy during low-cost periods for use during high-cost periods, reducing operational expenses.

The Future of Utility-Scale Batteries

As battery technology continues to advance, its role in power generation will expand. Next-generation chemistries, improved manufacturing processes, and enhanced recycling systems are expected to reduce costs and environmental impact. Additionally, increased investment in renewable energy integration will further drive the adoption of utility-scale batteries.

For engineers, the challenge lies in designing systems that balance the capabilities of batteries with the reliability of traditional generators. By leveraging the strengths of both technologies, hybrid systems can provide cleaner, more efficient, and more reliable power solutions for critical applications.

Utility-scale batteries represent a crucial step in the transition to a sustainable energy future, proving that with innovation and collaboration, the goal of reducing reliance on fossil fuels is within reach.

Hydrogen Fuel Cells: The Next Frontier

Hydrogen fuel cells are rapidly emerging as a transformative solution in the pursuit of sustainable and emissions-free power generation. By harnessing the chemical energy of hydrogen and oxygen, these cells generate electricity with water vapor as the sole byproduct, making them an attractive option for mission-critical backup power and grid-scale energy systems. While still in the early stages of widespread adoption, hydrogen fuel cell technology holds enormous potential for engineers seeking to design cleaner, more reliable power systems.

How Hydrogen Fuel Cells Work

A hydrogen fuel cell generates electricity through an electrochemical process, bypassing the combustion step entirely. The most common type, the Proton Exchange Membrane (PEM) fuel cell, operates as follows:

- Hydrogen Supply: Hydrogen gas (H₂) is supplied to the anode side of the fuel cell, where a catalyst splits it into protons (H⁺) and electrons (e⁻).

- Electron Flow: The electrons are directed through an external circuit, generating an electric current that powers connected systems.

- Proton Transfer: Protons pass through the polymer electrolyte membrane to the cathode.

- Oxygen Reaction: At the cathode, oxygen (O₂) combines with the electrons and protons to form water (H₂O) as a byproduct.

This process is highly efficient, quiet, and produces zero harmful emissions, making it ideal for applications requiring clean energy.

Applications and Benefits of Hydrogen Fuel Cells

Hydrogen fuel cells are particularly well-suited for applications that demand reliable, scalable, and eco-friendly energy solutions. Their advantages include:

Emissions-Free Operation:

With water as the only byproduct, hydrogen fuel cells contribute zero greenhouse gases or pollutants during operation. This makes them ideal for urban environments and industries under pressure to meet stringent environmental regulations.High Efficiency:

Hydrogen fuel cells achieve higher efficiencies compared to traditional combustion-based generators. Their ability to convert chemical energy directly into electrical energy minimizes energy losses.Scalability:

Fuel cells can be scaled to meet diverse power requirements, from small-scale applications to multi-megawatt installations for industrial or data center use.Quiet Operation:

The absence of moving parts in the fuel cell stack results in near-silent operation, reducing noise pollution and making them suitable for noise-sensitive environments.Renewable Hydrogen Potential:

When paired with renewable energy sources like solar or wind, hydrogen fuel cells can achieve true sustainability. Excess renewable energy can be used to produce green hydrogen through electrolysis, creating a closed-loop, zero-carbon system.

Challenges and Limitations

Despite their potential, hydrogen fuel cells face several significant challenges that must be addressed to enable widespread adoption:

Hydrogen Production and Infrastructure:

- Production: Most hydrogen today is produced via steam methane reforming (SMR), which is carbon-intensive. Transitioning to green hydrogen, produced through electrolysis powered by renewable energy, is critical for sustainability but remains cost-prohibitive on a large scale.

- Storage and Distribution: Hydrogen is a low-density gas, requiring compression or liquefaction for storage and transport. This increases logistical complexity and cost.

Cost of Technology:

Fuel cell stacks rely on expensive materials, such as platinum for the catalyst. Advances in catalyst research and manufacturing processes are needed to reduce costs.Durability and Lifespan:

Hydrogen fuel cells must withstand prolonged use in harsh environments. Membrane and catalyst degradation can impact performance, necessitating ongoing maintenance and eventual replacement.Safety Concerns:

Hydrogen is highly flammable, and its storage and handling require stringent safety protocols. While these challenges are manageable, public perception of hydrogen safety may hinder adoption.Energy Requirements for Green Hydrogen:

Producing green hydrogen through electrolysis requires significant energy input. Engineers must design systems that integrate renewable sources effectively to ensure economic viability.

Advances in Hydrogen Fuel Cell Technology

Engineers and researchers are making strides to address the limitations of hydrogen fuel cells and unlock their full potential. Key advancements include:

High-Performance Catalysts:

Developing non-platinum catalysts, such as those based on nickel or cobalt, can significantly reduce costs while maintaining performance.Solid Oxide Fuel Cells (SOFCs):

Unlike PEM fuel cells, SOFCs operate at high temperatures and can use a variety of fuels, including hydrogen and natural gas. Their versatility and efficiency make them promising for industrial applications.Modular Systems:

Modular fuel cell designs enable easy scaling, repair, and integration into hybrid systems. These configurations allow for tailored solutions to meet specific power demands.Electrolysis and Hydrogen Storage Innovations:

Advancements in electrolysis technology, such as polymer electrolyte membrane (PEM) and solid oxide electrolyzers, are improving the efficiency and scalability of green hydrogen production. Similarly, hydrogen storage systems are evolving, with metal hydrides and cryogenic solutions offering safer and more efficient alternatives.Integrated Systems:

Combining hydrogen fuel cells with renewable energy sources, batteries, and advanced control systems creates hybrid setups that maximize efficiency and reliability. For example, during periods of high renewable energy production, excess energy can be used to produce hydrogen, which is stored and later converted back to electricity when renewable sources are unavailable.

Practical Applications of Hydrogen Fuel Cells

Hydrogen fuel cells are gaining traction in several key sectors:

Data Centers:

Hyperscale data centers are testing hydrogen fuel cells as a clean alternative to diesel generators for backup power. In one trial, a 250-kilowatt hydrogen fuel cell system successfully powered server racks for 48 consecutive hours.Transportation:

Fuel cell technology is being deployed in hydrogen-powered vehicles, including buses, trucks, and trains, demonstrating its versatility and scalability for clean mobility solutions.Grid-Scale Energy Storage:

Hydrogen can serve as an energy carrier, enabling large-scale storage of surplus renewable energy. Electrolyzers convert excess electricity into hydrogen, which can be stored and later converted back to electricity during periods of high demand.Industrial Applications:

Industries requiring high-temperature processes, such as steelmaking and chemical production, are exploring hydrogen as a clean energy alternative to natural gas and coal.Remote Power Systems:

Hydrogen fuel cells are being deployed in remote locations where traditional grid access is limited, providing a reliable and clean energy source.

The Road Ahead for Hydrogen Fuel Cells

Hydrogen fuel cells represent a critical component in the transition to a cleaner energy future. While challenges remain, ongoing research and development efforts are driving down costs, improving durability, and expanding the use cases for this technology. As renewable energy adoption accelerates, the role of hydrogen as a complementary energy storage and generation solution will become increasingly prominent.

For engineers, hydrogen fuel cells offer an exciting opportunity to design systems that are not only sustainable but also highly reliable and adaptable. By integrating hydrogen fuel cells into hybrid configurations alongside renewables and other technologies, engineers can create power systems that meet the demands of the modern world while minimizing environmental impact.

The future of hydrogen fuel cells is bright, and as innovation continues to overcome current barriers, their deployment will help pave the way toward a carbon-neutral energy ecosystem.

The role of technical knowledge in building a sustainable future

The journey toward clean energy requires not only technological innovation but also collaboration among engineers, policymakers, and manufacturers. By staying informed about the latest advancements and adopting a proactive approach to sustainability, engineers can play a pivotal role in reducing the environmental footprint of power generation systems.

Key strategies include:

- Research and Development: Investing in R&D to improve existing technologies, such as biofuel-compatible engines and high-capacity batteries.

- Partnerships: Collaborating with renewable energy providers to integrate solar, wind, and hydrogen solutions into backup power systems.

- Education and Advocacy: Promoting awareness of sustainable practices and technologies among stakeholders and end-users.

The path to cleaner power generation is both challenging and exciting. By embracing a combination of evolutionary improvements and revolutionary breakthroughs, engineers can drive the transition to sustainable energy systems. From optimizing diesel efficiency to exploring hydrogen and battery technologies, the possibilities are vast.

Ultimately, the success of these efforts hinges on the commitment of technical professionals to innovate and adapt. With the right knowledge and tools, the goal of producing clean and ecological energy is not only achievable but also essential for a sustainable future.