Maintaining diesel generators demands attentiveness, especially when confronting engine slobber or wet stacking – a condition where unburned fuel accumulates in the exhaust, reducing efficiency and hastening engine degradation. This issue often arises from operating generators at minimal loads, a byproduct of incorrect sizing or the lack of sufficient loads during testing phases. The conventional approach to mitigate this involves using external load banks, a process that increases emissions and fuel expenditures.

UNDERSTANDING WET STACKING

Engines operating under 30% capacity for prolonged periods struggle to reach and maintain the temperatures necessary for complete fuel combustion. This discrepancy leads to a drop in combustion chamber pressure below that of the crankcase, preventing full expansion of piston rings and sealing off the chamber effectively.

THE CONSEQUENCES OF WET STACKING

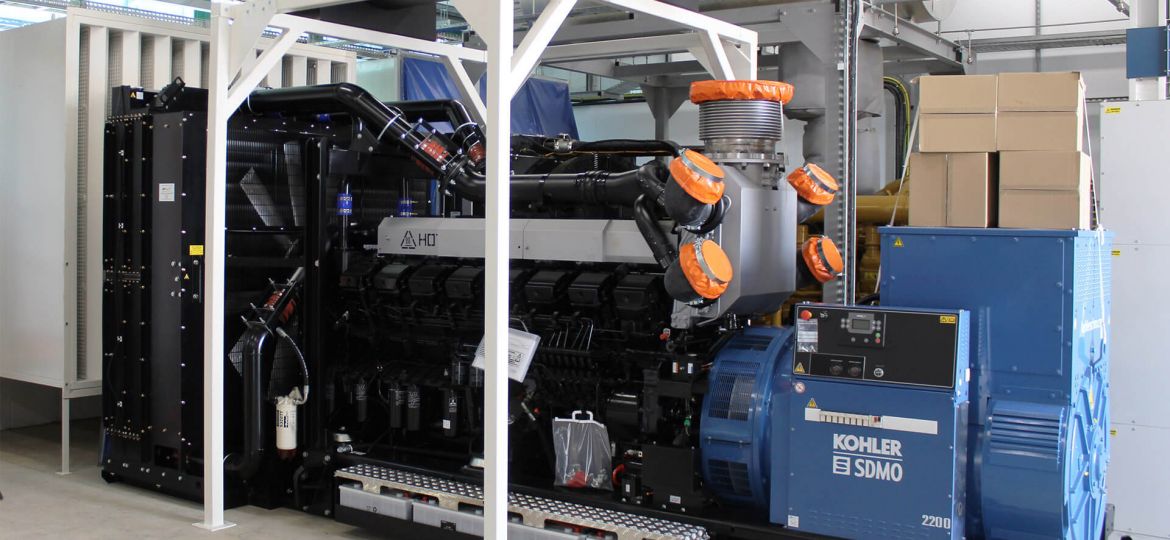

Illustrated in Figure 1, the repercussions of wet stacking extend to the fouling of fuel injectors, excessive wear on valve guides, and potential harm to pistons, their liners, and rings.

CONSIDERATIONS ON EMISSIONS

The confluence of reduced engine lifespan, elevated maintenance expenses, and the challenge of complying with stringent emission standards exacerbate the woes of wet stacking.

THE CRITICAL NATURE OF WET STACKING

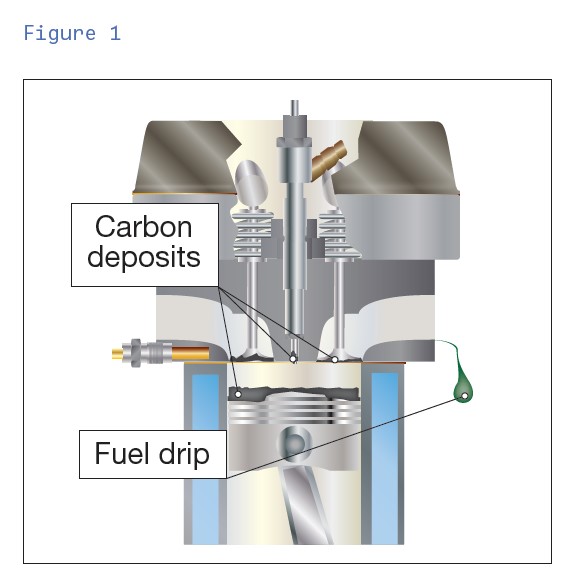

Further complicating the issue, the incorporation of new emission control technologies such as diesel oxidation catalysts (DOC), selective catalytic reduction (SCR) units, and diesel particulate filters (DPF) by generator manufacturers demands attention (see Figure 2). These technologies falter under low-load operations, jeopardizing the attainment of emission benchmarks, especially concerning the requisite exhaust temperature ranges for SCR and DPF systems.

TACKLING WET STACKING

Historically, the remedy involved monthly generator exercises at 30% capacity to eliminate fuel remnants or prevent their accumulation. Nonetheless, technological advancements have reduced the necessity of such costly routines, suggesting that modern diesel generators might only need to operate at 30% capacity annually for optimal functionality and emission compliance.

THE IMPORTANCE OF ADDRESSING WET STACKING

Though initially non-damaging, wet stacking gradually undermines engine performance and longevity. In severe instances, the exhaust could ignite upon rapid introduction to high temperatures.

THE STRATEGY OF LOAD-BANK TESTING.

AVOIDING WET STACKING WITH MINIMUM LOADS

The most straightforward method to prevent wet stacking involves operating the generator at the recommended minimum load by the manufacturer. This approach often entails using a load bank for monthly testing, intensifying the load on the generator to eradicate accumulated deposits. Manufacturers typically advise a 30-minute run at a minimum during these monthly load bank tests.

RECONSIDERING LOAD-BANK TESTING METHODS

With technological progression simplifying monthly testing, it’s pivotal for facilities to update their maintenance protocols, historically unchanged for years and possibly outdated.

UPGRADING DIESEL ENGINE OPERATION

EMBRACING LATEST DIESEL TECHNOLOGIES

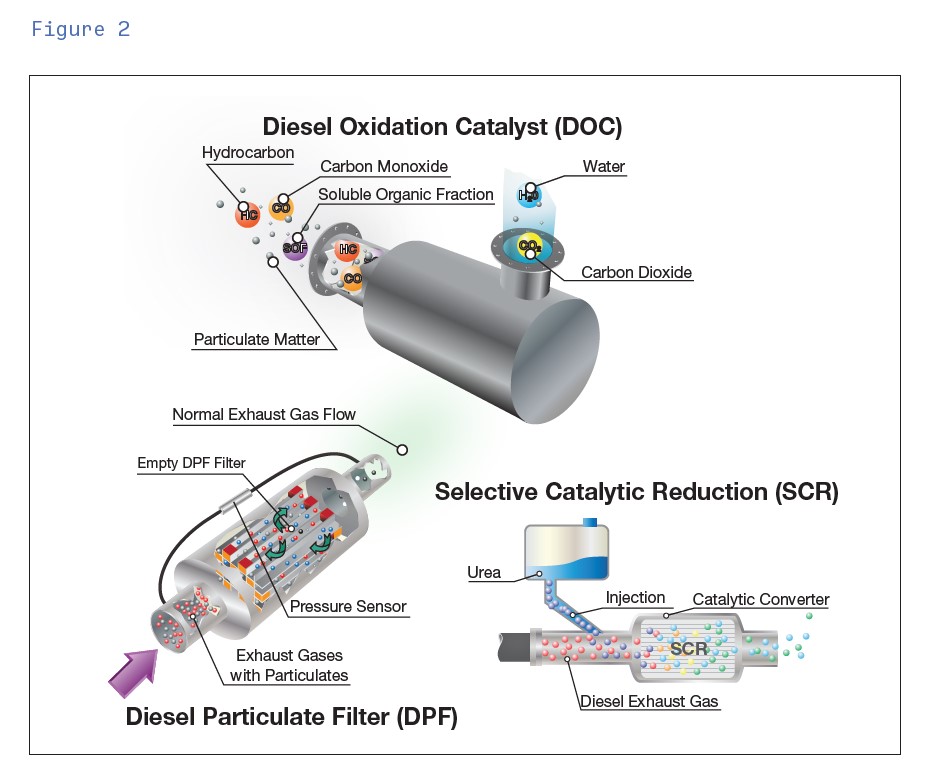

Modern diesel engines benefit from innovations that enhance efficiency and minimize the unburnt fuel escape. These include the implementation of common rail systems for improved fuel atomization, charge air cooling for more effective air delivery, and more precisely engineered piston and ring assemblies. These advancements amalgamate to curtail conditions conducive to wet stacking, allowing for reduced load during exercises (refer to Figure 3).

REASSESSING MAINTENANCE PREMISES. EXPERIENCES FROM THE KOHLER® KD SERIES™ FIELD.

Enhancements in efficiency offer generator operators the chance to revisit and possibly alleviate the stringent load-banking schedules previously deemed necessary. Based on trials and field data, generators like the KOHLER KD Series can undergo unloaded exercises monthly, with annual load bank testing satisfying most operational standards.

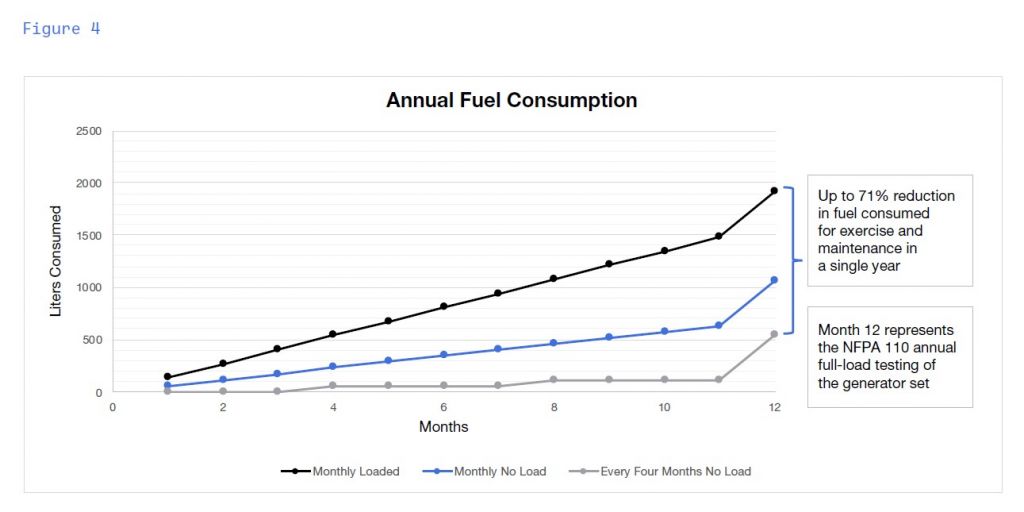

TRANSITIONING TO ANNUAL LOAD TESTING

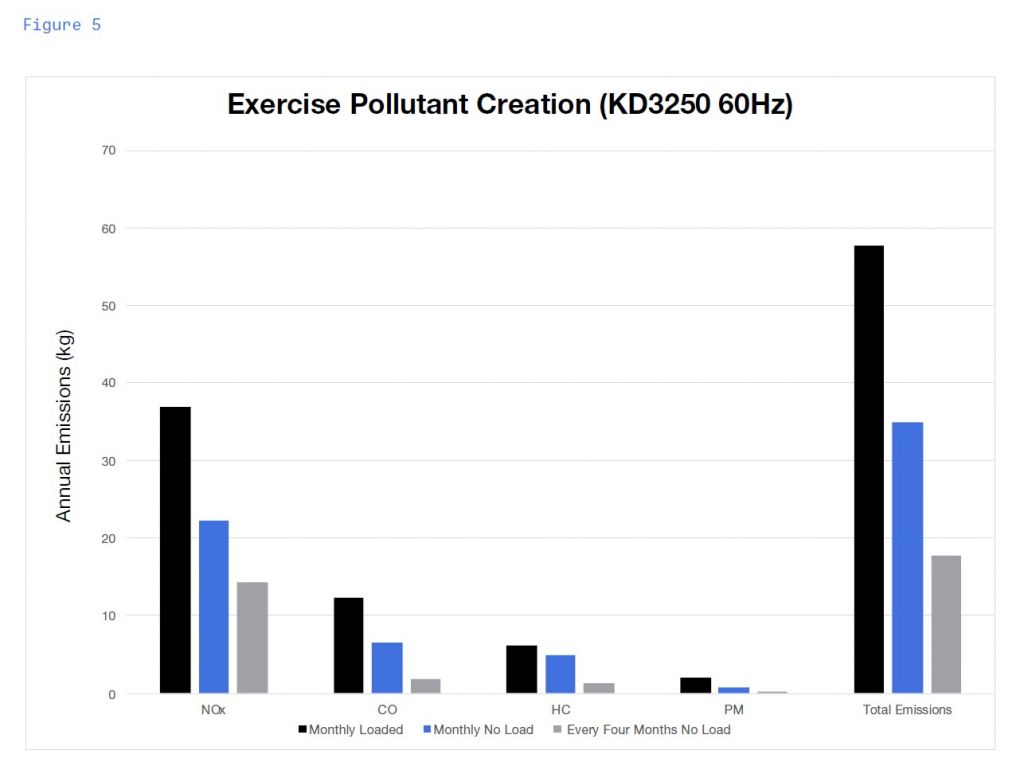

Transitioning to annual testing can yield significant savings – a 3250-kilowatt generator’s example showcases a dramatic reduction in annual fuel consumption and pollutant emission by adjusting the testing frequency. Figures 4 & 5 display these savings alongside the diminished on-site operational costs. This shift also aligns with NFPA110 regulations, which mandate monthly 30-minute exercises under specific conditions.

Figure 4: Yearly Fuel Usage

Figure 5: Pollutant Production during Testing (KD3250 60Hz)

REVAMPING MAINTENANCE STRATEGIES.

CONSULTATION WITH BRAGS & HAYES SERVICE.

Before altering maintenance plans, consulting with Brags & Hayes service departament or manufacturers is crucial, particularly to accommodate various after-treatment systems. This ensures compliance with regional emission standards and optimizes the choice of after-treatment technologies.

This strategic approach to diesel generator maintenance, emphasizing technological advancements and operational efficiency, underscores the importance of adapting to modern methodologies for enhanced performance and sustainability.