In this post we will continue to delve into the Generator Set Application and Rating Guidelines so that you can understand what type of power generator product to purchase to meet your needs.

When it comes to investing in a generator set, the decision isn’t just about selecting a brand or model. It’s about understanding how generators are rated, their applications, and the specific conditions under which they’ll operate. This guide provides a detailed breakdown of generator rating categories, application considerations, and crucial factors affecting performance, such as altitude and temperature adjustments.

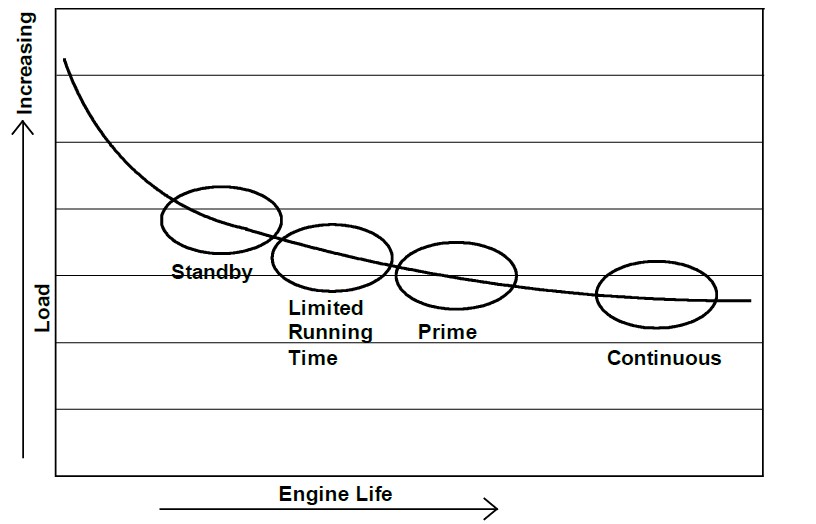

Generator sets are categorized into four main ratings: standby, prime, limited running time, and continuous. Each rating corresponds to specific use cases and operational conditions.

Standby Rating (ISO 8528-1 ESP)

Standby generators are intended for emergency power during outages. They operate for a limited number of hours annually—typically up to 200, but some models can handle up to 500 hours. Importantly, standby generators lack overload capability and cannot exceed their rated capacity. They comply with ISO 8528-1 standards.

Key Formula for Standby Generators:

This formula considers power usage over time, providing a snapshot of a generator’s capacity for backup purposes.

Where:

- Average Power is determined based on power consumption over specific time intervals.

- Load Factor represents the generator’s usage intensity.

Prime Rating (ISO 8528-1 PRP)

Prime-rated generators are designed for applications with variable loads and allow for unlimited annual operation. They can handle up to 10% overload for one hour every 12 hours. This makes them suitable for more demanding situations where reliability is paramount.

The load factor takes into account the average percentage of the generator’s capacity being utilized.

Note: Loads below 30% of the generator’s capacity are counted as 30%.

Limited Running Time Rating (ISO 8528-1 LTP)

Generators with this rating deliver power for non-varying loads over a limited duration, capped at 500 operational hours per year. They are ideal for controlled scenarios, such as testing or occasional supplementary power.

Continuous Rating (ISO 8528-1 COP)

Continuous-rated generators provide consistent power for an unlimited number of hours with non-varying loads. They are used in situations like data centers or factories requiring uninterrupted operation.

Application Considerations: Stationary vs. Non-Road

Stationary Applications

- Emergency Use: Back-up for utility power, with minimal annual operational hours.

- Non-Emergency Use: Regular power for peak shaving or unreliable grid connections, requiring prime or continuous ratings.

Non-Road Applications

Mobile generators used in multiple locations throughout the year fall under this category. Their flexibility suits construction sites or temporary installations.

Factors Influencing Generator Performance

Load Management

The generator’s life expectancy and efficiency depend heavily on the load it carries. Overloading or underloading impacts wear and fuel efficiency. For instance:

- Standby Load: Engines running at higher loads may face more frequent maintenance.

- Prime Load: Requires balanced operation for long-term reliability.

Environmental Adjustments: Temperature and Altitude

Environmental conditions like altitude and temperature directly impact generator performance. Manufacturers provide derating tables to calculate adjustments for optimal operation.

Temperature and altitude adjustments (derating) are critical for ensuring optimal generator performance. High altitudes reduce air density, affecting engine combustion, while elevated temperatures challenge cooling systems.

Example of Derate Calculations

- Temperature Adjustment: Generators derate by 1% for every 10°C above a specific threshold.

- Altitude Adjustment: A reduction of 0.5% per 100 meters above 2500 meters is common.

Tables for Specific Models:

- Model 20kW Example: At 50°C and 2700 meters, the derate factor is 0.980. The corrected output:

- kW: 26×0.980=25.526 \times 0.980 = 25.526×0.980=25.5

- kVA: 33×0.980=32.333 \times 0.980 = 32.333×0.980=32.3

Altitude and Temperature Derate Example

Key Notes on Using Derate Tables:

- Altitude Impact: As elevation increases, air density decreases, reducing combustion efficiency.

- Temperature Impact: Higher temperatures strain cooling systems and decrease power output.

| Altitude (m) | Altitude Derate Factor | Temperature (°C) | Temperature Derate Factor |

|---|---|---|---|

| 0–300 | 1.000 | 0–25 | 1.000 |

| 600 | 0.987 | 40 | 0.975 |

| 900 | 0.948 | 50 | 0.940 |

| 1500 | 0.870 | 55 | 0.910 |

- Altitudes above 300 meters require a derate of 0.5% per 100 meters, reducing the generator’s effective power.

- Temperatures above 25°C cause additional derating, typically at 1% per 10°C increase.

Application-Specific Derate Tables

Below are examples for various models and conditions:

Model | Altitude (m) | Temperature (°C) | Derate Factor |

|---|---|---|---|

| KG40 | 2100 | 25 | 1.000 |

| KG80 | 1500 | 50 | 0.980 |

| KG150 | 1200 | 45 | 0.940 |

These adjustments help align expectations for power delivery in real-world conditions.

Explaining Load and Derating Impact

Example Calculation

Scenario:

- Generator model: KG80

- Altitude: 1200 meters

- Temperature: 45°C

Using the derate factors:

- Altitude Adjustment: Initial Factor=1.000−(1.3%×(1200−200)/100)=0.980\text{Initial Factor} = 1.000 – (1.3\% \times (1200-200)/100) = 0.980Initial Factor=1.000−(1.3%×(1200−200)/100)=0.980

- Temperature Adjustment: Adjusted Factor=0.980−(2.0%×(45−25)/10)=0.940\text{Adjusted Factor} = 0.980 – (2.0\% \times (45-25)/10) = 0.940Adjusted Factor=0.980−(2.0%×(45−25)/10)=0.940

- Output Power: If the generator’s rated power is 100kW: Corrected Power=100×0.940=94kW\text{Corrected Power} = 100 \times 0.940 = 94 \text{kW}Corrected Power=100×0.940=94kW

Key Metrics to Consider

Mean Time Between Overhauls (MTBO)

The MTBO curve indicates how engine loads impact service intervals. Engines running at lower loads generally require less frequent maintenance.

MTBO (Mean Time Between Overhauls) Curve Analysis

The MTBO curve illustrates how engine load impacts the intervals between required overhauls:

- Higher Loads: Shorten the interval.

- Lower Loads: Extend the interval.

MTBO by Load

| Load Category | Typical MTBO Interval |

|---|---|

| Standby Load | Long (Intermittent Use) |

| Prime Load | Moderate |

| Continuous Load | Short |

Chart Analysis:

- Continuous Load: Shorter MTBO.

- Standby Load: Longer MTBO due to intermittent operation.

Fuel Type and Quality

Generator performance and longevity also hinge on fuel type and quality. Dual-fuel engines, for example, have different efficiency ratings for natural gas versus liquefied petroleum gas.

Choosing the Right Generator

When selecting a generator, it’s imperative to match the rating and application to your specific needs. Whether for backup, prime, or continuous power, understanding these factors ensures your investment delivers reliable performance. Moreover, paying attention to environmental factors and load management can extend the life of your generator, making it a valuable asset for years to come.

By understanding the application-specific ratings, environmental impacts, and model-specific tolerances, you can ensure that your generator set meets your operational needs efficiently. Remember, proper planning and adherence to derating guidelines will maximize your investment and ensure reliability under all conditions.

This guide provides the insights you need to make an informed generator purchase. By understanding generator ratings, environmental adjustments, and specific model capabilities, you can select the perfect generator for your requirements. Ensure you refer to the provided derating tables to calculate accurate power outputs based on your location and conditions. For technical support or further customization, please consult our technicians at Brags & Hayes Generators who will be happy to help you..