At the heart of a power system, you’ll find its controllers. Day in and out, they stay vigilant — constantly observing and adeptly administrating operating conditions to guarantee not only the reliability of your equipment, but its adaptability and performance too. And in scenarios that threaten damage? They’re your equipment’s staunch defenders.

At Brags & Hayes Generators we sale KOHLER controllers, the design and manufacture of KOHLER controllers are crafted entirely in-house – lending an unparalleled edge to their dependability. They present an intuitive interface, making them simple-to-use, while steadfastly maintaining safety. And the cherry on top? They flawlessly integrate with all of our other equipment. So rest easy — with KOHLER controllers, you’re entrusting your power system with unmatched quality and proficiency.

In this post we will try to make a detailed review of everything related to Kohler controllers so that it can serve as a reference for you to choose the most suitable Kohler controller for your project.

Generator power systems, and controllers specifically, involve highly complex interactions between mechanical, electrical, and electronic systems. As you evaluate your needs and consider your options, use this glossary of useful terms to enhance your controllers research.

LOAD MANAGEMENT

Load management allows you to prioritize loads and remove noncritical loads when the power supply becomes unable to support the entire demand.

Each load is assigned a priority level. Load management determines when priority levels are signaled to disconnect (shed) and reconnect (add). When multiple generators are online, load management matches the load to the generator capacity.

The system can control feeder breakers or transfer switches. Dry contacts or communications can be provided to interface with your building-management system.

In a paralleled generator system, it is imperative to plan for the unlikely event of a generator failure. Removing or shedding load prevents the remaining online generators from overloading and tripping offline.

Load Add

Loads can be added based on several considerations, including:

- Generator bus capacity: loads are added based on the kW capacity of the bus and an assumed kW demand of the load.

- kW overload: When the generators reach their overload setpoints, low-priority loads sequentially shed until the load falls below the overload setpoint.

- Number of generators online: loads are added based on how many generators are connected to the bus; this is most effective in systems with same-size generators.

Load Shed

A load-shed event can be triggered by several causes, including:

- Generator failure: Loads are shed based on the number of failed generator sets.

- Underfrequency: This is often an indication that the generators are fully loaded and cannot supply additional power to the load. When the bus frequency reaches its underfrequency setpoint, preset loads are shed.

GENERATOR MANAGEMENT

Generator management optimizes the number of online generators based on the load’s kW demand, starting and stopping them as required. Generators are sequenced on in order of operator-assigned priority (or based on runtime) and taken off in reverse priority. Operator-defined setpoints determine the load level percentage and time delay at which the genset will be brought on or taken offline.

VOLTAGE REGULATION

Voltage regulation helps to minimize voltage fluctuations and quickly stabilize the system when equipment is added or removed. A common experience of voltage fluctuation is when a piece of equipment is turned on and the lights dim or a fan slows down for a moment. While not detrimental to most commercial and industrial equipment, these fluctuations can be distracting.

Generator voltage can be affected by both engine speed and current, and it can be adjusted either manually or through software. Controllers are responsible for detecting and quickly responding to voltage fluctuations, typically maintaining a range between 0.25% and 0.50%.

NFPA 110

NFPA 110 is the National Fire Protection Association’s performance standard for emergency and standby power systems. An individual product cannot be marked as NFPA 110-compliant; the overall power system must be installed, maintained, tested, and operated per the NFPA standard to be compliant. Kohler is committed to designing emergency and standby power components with features that ensure the power system’s compliance with NFPA 110.

NFPA 110 has identified two levels of requirements that pertain to the installation, performance, and maintenance of the power system:

- Level 1 pertains to power systems where failure to perform could result in loss of life or serious injury.

- Level 2 pertains to power systems where failure to perform is less critical to human life and safety.

The installation, performance, and maintenance requirements associated with a power system depend upon the power system level.

KOHLER® controllers are designed to meet the requirements of NFPA 110. Key features include:

- Emergency stop.

- Master switch including Stop/Run/Auto controls.

- Audible horn, visual warnings, and visual fault indicators.

- System faults and status monitored and annunciated on both the controller display and remote annunciator.

PROGRAMMABLE I/O

Every job is unique and using a controller that allows for customization to support your needs is critical. Controllers offer programmable inputs and outputs to help with the customization.

Inputs are external signals the controller receives from various connected monitoring and management systems, which the controller can then process and respond to based on its programming. Likewise, outputs are information about the generator and/or automatic transfer switch operating conditions that the controller provides to external systems.

- Analog Inputs and Outputs: These are typically used for sensors that show varying amounts of a given metric, such as fuel level in a diesel tank. Analog inputs and outputs identify a system state within a range of values, typically from 0% to 100%.

- Digital Inputs and Outputs: These are used for sensors that show a high or low state, such as an alarm, which is either active or inactive. As an example, a power system can be programmed to trigger a remote shutdown when an input reports a high state.

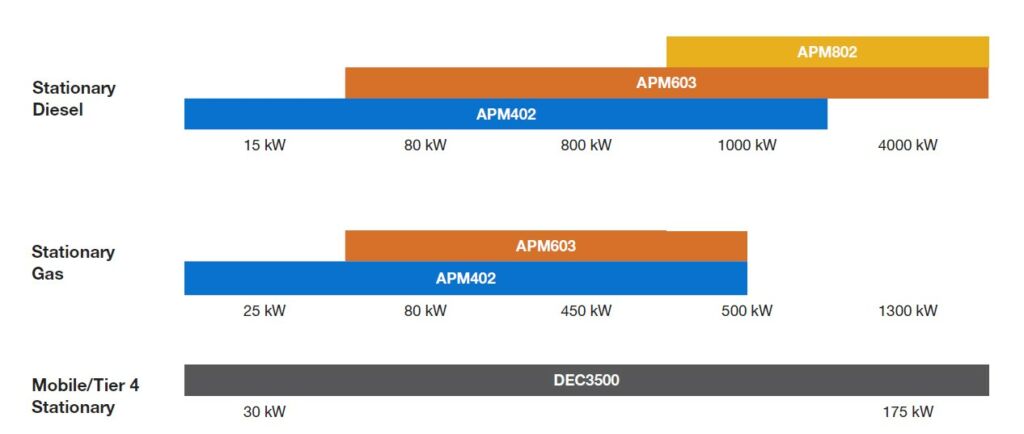

Kohler CONTROLLERS for GENERATOR SET

Available to support either single generator or parallel operation, Kohler generator controllers are easy to operate and provide dependable engine and alternator control, operating information, and system diagnostics.

Advanced Power Management

- APM402: Single Generator

- APM603: Single/Parallel Generators

- APM802: Single Generator

Decision-Maker®

- DEC3500: Single/Parallel Generators

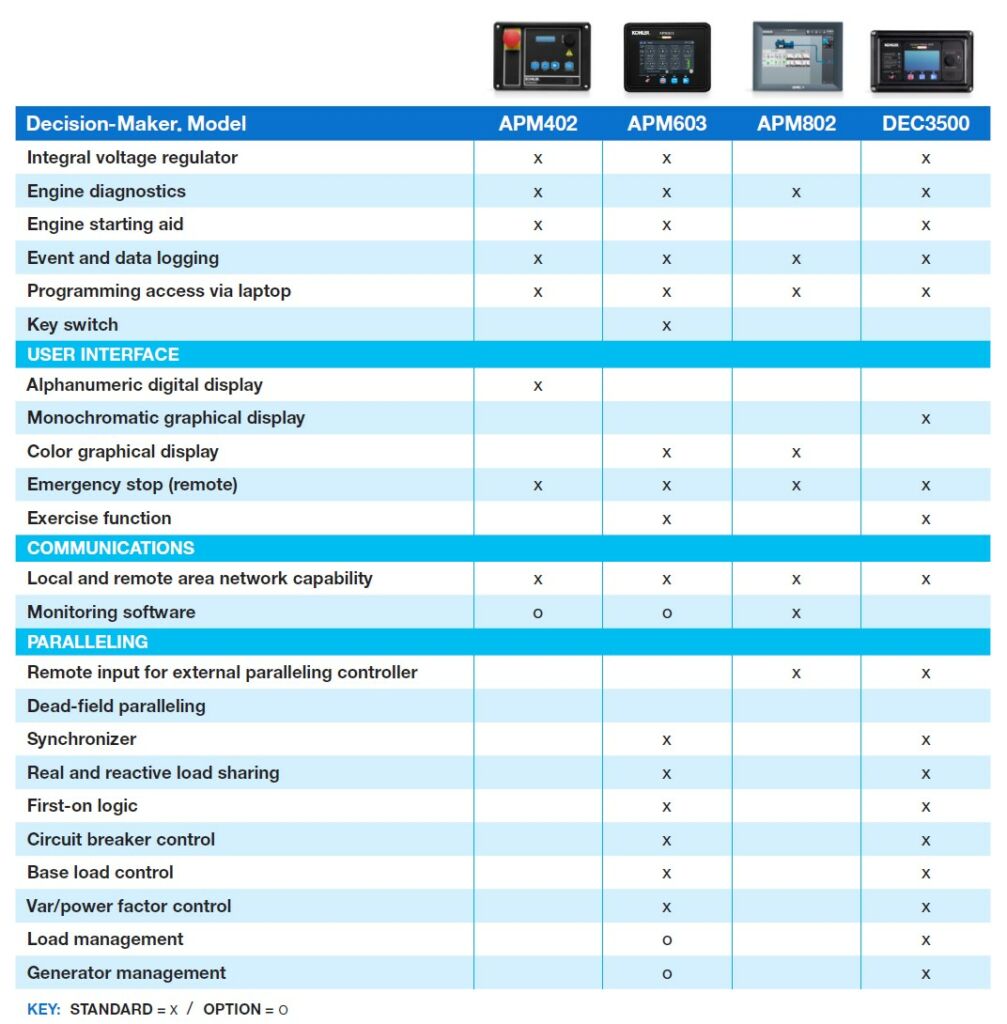

Kohler CONTROLLERS COMPARISON

Kohler controllers do not attempt to have a one-size-fits-all solution. Kohler controllers are designed in custom packages tailored to your needs, from basic controllers that manage a single node to more advanced models that allow multiple generators to be connected in parallel.

Kohler makes each controller easy to operate, with user-friendly displays and intuitive navigation. Plus, all of Kohler controllers feature advanced network communications for remote monitoring as well as adjustable parameters to accommodate your specific application.

Kohler controllers features

STANDARD FEATURES

Tested and Approved: Kohler controllers meet NFPA, UL, and CE standards.

Integral Voltage Regulator: KOHLER controllers deliver precise voltage regulation to protect your sensitive equipment from poor power quality.

Seamless System Integration: Every controller works with our entire range of automatic transfer switches and switchgears for complete system integration.

Alternator Protection: This must-have technology protects the alternator from thermal overload.

COMMON FEATURES

Inputs and Outputs: All models include digital and analog input and output with option for additional inputs/outputs.

Engine Status and Condition Indicators:

- Oil pressure/temperature.

- Coolant temperature.

- Engine speed.

- Number of starts.

- Battery voltage

Alternator Status and Condition:

- Voltage, L-L and L-N for all phases.

- Current.

- Frequency for all phases.

- Total kW.

- Power factor.

- Per phase kW/kVA and kVAR.

Engine Protection–Shutdown/Indication:

- High engine coolant temperature.

- Low coolant level.

- Low oil pressure.

- Overcrank.

- High fuel level/pressure.

- Low fuel level/pressure.

- Overspeed.

- Load-shed output.

Alternator Protection–Shutdown/Indication:

- Over/under voltage frequency.

- Overcurrent.

- Overpower.

- Locked rotor.

- Reverse power/VAR

SPECIFIC MODELS FEATURES

APM402

The APM402 generator set controller provides basic control, system monitoring, and system diagnostics for optimum performance. The APM402 controller meets NFPA 110, Level 1 when equipped with the necessary accessories and installed per NFPA standards.

DISPLAY, INTERFACE, AND ACCESSIBILITY

- A digital display and push-button/rotary selector dial provide easy

local access to data. - The scrolling display shows critical data at a glance.

- The controller supports Modbus protocol. Use with serial bus or Ethernet networks. (Ethernet requires an external Modbus/Ethernet converter module).

- Integrated hybrid voltage regulator provides +/- 0.5% regulation.

- Built-in alternator thermal overload protection.

- Simple programmable function for input and output configuration.

ONBOARD DIAGNOSTICS

- Immediate visibility for up to 1,000 events including warnings and faults.

- Intuitive descriptions of ECM fault codes.

APM603

The APM603 generator set controller provides advanced control, system monitoring, and system diagnostics for a single generator set or for paralleling multiple generator sets. The APM603 connects the generator set to other power system equipment and network- management systems using standard industry network communications. It uses a patented hybrid voltage regulator with unique software logic to manage alternator thermal overload protection and serve as an overcurrent protective device features that normally require additional hardware. The APM603 controller meets NFPA 110, Level 1 and UL6200, the newest UL standard for generator controllers.

DISPLAY, INTERFACE, AND ACCESSIBILITY

- Intuitive, dynamic 7.5-inch interface with backlight displays key data for easy local access to data.

- Overview screen can be customized to show critical data at a glance.

- Create a custom favorites list for quick access to important data.

- Supports Modbus protocol through serial bus and Ethernet networks, and supports SNMP and BACnet through Ethernet networks.

- Integrated hybrid voltage regulator providing +/- 0.25% regulation.

- Built-in alternator thermal overload protection.

- Real-time clock with battery backup.

- Integrated programmable logic function for advanced input and output configuration.

- Isochronous load sharing ensures that work is distributed evenly across the power system, reducing stress on individual generator sets.

ONBOARD DIAGNOSTICS

- Immediate visibility of warnings and faults with text description and code display.

- 15 seconds of critical data captured around each warning and fault.

- Store up to 3,000 events locally and download to external USB drive.

- Data logging of customized parameter list for report generation and advanced troubleshooting. Store to external USB drive for easy export and in-depth data analysis.

- Intuitive descriptions of ECM fault codes.

ONBOARD PARALLELING

- Parallel up to eight generator sets.

- Automatic synchronizer with random first-on logic built into controller ensures the first available generator is used to power loads while remaining generators synchronize to the bus.

- Integrated protective relays guard power system from potentially harmful operating scenarios

- Configurable load management of up to 16 loads allows you to shed lower-priority loads if needed to ensure critical loads are always powered.

- Built-in generator management extends maintenance intervals, conserves fuel,

and ensures system longevity.

APM802

The APM802 generator set controller provides advanced control, system monitoring, and system diagnostics for optimum performance. The APM802 controller meets NFPA 110, Level 1 when equipped with the necessary accessories and installed per NFPA standards.

DISPLAY, INTERFACE, AND ACCESSIBILITY

- Intuitive, dynamic 12-inch touch-screen interface with backlight displays key data for easy local access to data.

- Supports Modbus RTU and TCP protocols.

- Real-time clock with battery backup.

- Integrated programmable logic function for advanced input and output configuration.

ONBOARD DIAGNOSTICS

- Immediate visibility for up to 1,000 events including warnings and faults.

- Two USB ports allow connection of a flash drive, mouse, or keypad.

- Electrical data, mechanical data, and system settings can be saved

to a USB drive. - Recording feature allows data collection of key values.

- Ethernet port allows connection to a PC-type computer and/or Ethernet switch.

- Intuitive descriptions of ECM fault codes.

DEC3500

The Decision-Maker® 3500 generator set controller provides advanced control, system monitoring, and system diagnostics for optimum performance and compatibility. The Decision-Maker 3500 controller meets NFPA 110, Level 1 when equipped with the necessary accessories and installed per NFPA standards.

DISPLAY, INTERFACE, AND ACCESSIBILITY

- A digital display and push-button/rotary selector dial provide easy local access

to data. - Graphical display shows critical data at a glance.

- The controller supports Modbus protocol. Use with serial bus or Ethernet networks. (Ethernet requires an external Modbus/Ethernet converter module).

- Integrated hybrid voltage regulator provides +/-0.5% regulation.

- Built-in alternator thermal overload protection.

- Encapsulated to protect against dust and dirt with sealed connectors.

- Simple programmable function for input and output configuration.

ONBOARD DIAGNOSTICS

- Immediate visibility for up to 1,000 events including warnings and faults.

- Intuitive descriptions of ECM fault codes.

ONBOARD PARALLELING

- Parallel up to eight generator sets.

- Automatic synchronizer with random first-on logic built into controller ensures the first available generator is power loads while remaining generators synchronize to the bus.

- Integrated protective relays guard power system from potentially harmful operating scenarios.

- Isochronous load sharing ensures that work is distributed evenly across the power system, reducing stress on individual generator sets.

- Configurable load management of up to six loads allows you to shed lower priority loads if needed to ensure critical loads are always powered.

- Built-in generator management extends maintenance intervals, conserves fuel, and ensures system longevity.

KOHLER® GENERATOR CONTROLLER COMPARISON

KOHLER generator controllers serve as indispensable tools within the realm of power generation. Their principal function involves the monitoring and management of several critical aspects necessary for the generator’s peak performance. Ranging from frequency regulation to fault protection, these specialized components play a pivotal role in maintaining the reliable operation of power systems.

The process of choosing a generator controller is multifaceted – gaining a clear understanding of the unique features of KOHLER’s controllers is crucial to guarantee robust performance and resilient response in challenging circumstances.

We trust that this article will serve as a valuable resource as you make an informed decision about selecting the appropriate KOHLER controller for your project.

Don’t hesitate to reach out for any further information or assistance regarding to power generator controllers. Contact us at the phone number +1.954.657.7777, or write to us at info@bnhgenerators.com, and we will gladly help you.